So there we were – broken down and ending up in Billings, MT – pondering our options to get back on the road.

Last Monday morning the techs at Interstate PowerSystems (where we had been hauled to over the weekend) confirmed what we already suspected – that the overheating almost certainly had caused non-trivial damage to our engine.

No matter what might have initially caused the problem, we had some serious repairs to make.

This is what we knew:

- The bus overheated shortly after cresting a hill, on a gradual downhill.

- On the way up the engine temp gauge had risen slightly, but was barely above 190 at the crest.

- After reaching the crest, the engine temperature spiked rapidly and within two miles had tripped the “Hot Engine” auto-shutoff right as Chris was reaching the first safe place to pull over.

- The engine boiled 12 gallons of coolant out the surge tank overflow onto the side of the road, but no hoses had burst and the coolant system wasn’t leaking.

- There is no coolant in the oil.

- Manually turning the engine, the mechanic still felt “good compression” throughout a full cycle.

- The engine starts easily, but doesn’t sound right.

- The engine is producing not enough power to move the bus at all.

- When the engine is running, a steady stream of oil flows out the blower box drain, and also there is oil flowing into the exhaust.

- When the engine is running, the lower bank of cylinders was not warming up – running 100 degrees cooler than the upper bank.

Since all the signs pointed to little chance for a quick, cheap, or easy fix – rather than spending time and money on additional diagnostics trying to figure out what went wrong, we asked Interstate to work up a quote for removing the engine and doing a complete rebuild.

We knew that a rebuild would almost certainly uncover the original problem, would repair the damage caused, and would also uncover any other issues that might be lurking inside.

While they went to work pricing all that work out, we dove into researching all of our other potential options for moving forward. Since we’re looking at a major cost regardless, it only made sense to explore all our options – repair, replace, rebuild or repower?

The research turned into a roller coaster of a week – physically, intellectually, and emotionally draining.

We are very thankful that Interstate Power has been extremely flexible and patient with us. They’ve actively encouraged us to do our own research, and did not pressure us at all to get started on the work we asked them to quote. They have graciously provided us electricity, water and internet to use while living in their parking lot. And even when options would be leading us away from having the work done at their shop, they were still enthusiastic in helping us pursue even those avenues forward.

Interstate Powersystems is the official Detroit Diesel shop for the region, and though 2-stroke engine expertise is growing exceedingly rare in most places, they actually have several 2-stroke mechanics on staff who have plenty of experience maintaining some of the heavy equipment in the area, including the powerful Yellowstone snow removal equipment and some huge oil field machinery.

We clearly had chosen wisely in picking where to be towed.

They are however not as familiar with particulars of vintage buses, which will have them thinking a bit outside their normal boxes. But fortunately, we have just enough knowledge and resources to draw on to help fill in those gaps.

We are also extremely grateful for our bus community. Since announcing our situation here, on Facebook, and on the bus forums we have been basking in the glow of support, advice and wisdom. Chris has pretty much had his earbuds implanted in his head all week as he’s taken calls non-stop from folks helping us think through the options. We’ve been in touch with several expert mechanics, bus gurus, and fellow full timing bus nomads – all with words of wisdom.

Sometimes they even agree with each other. *grin*

It’s been a whirlwind of a week settling on a plan of action, but at last a decision is made. Read on to learn how we reached it…

Our preface

We’re going to preface this all by being very upfront and clear here that we are not viewing this breakdown as anything close to a disaster.

Remember that when we bought Zephyr two years ago, we made our lowball purchase offer based in part considering the fact that she had a completely unknown mechanical history. Her original loving owner (and the original converter from seated coach to RV) had passed away in the mid-1990s, the second owner had barely used her and was deceased as well, and the person we were buying her from had bought her at an auction to flip – and he knew nothing about the condition of the engine other than “it starts right up”.

We barely knew what a 2-stroke was at the time and had no way to make a proper evaluation, so we consciously took a gamble.

We dove in head first – but with eyes wide open.

We had set a first year acquisition budget when we went out bus hunting, and we were comfortable spending either the entire budget on the exact ‘right bus’ in excellent mechanical condition, or less on a bus that we could then modify to make our own. Zephyr’s listed price of $12k was already on the very low end of buses we were considering, and we acquired her for a sweet $8k.

We listened to the wisdom of the bus community and factored in the potential for a major engine repair, on top of our anticipated general maintenance (tires, wheels, suspension, fluids, brakes, etc.), and planned that we might face this expense sooner or later.

We were thrilled that our initial mechanical inspections after purchase by some bus gurus declared that we had found a ‘strong runner’, but we still socked the money away. With an engine that old and with so many unknowns, you can never be too sure.

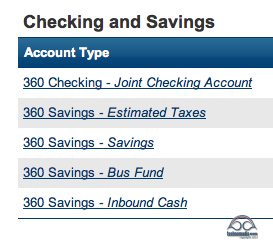

We’ve had the money for major engine work sitting in an accessible bank account collecting bits of interest for the past 2 years. We knew if we encountered this situation, we never wanted to feel stuck needing to liquify assets to pay for it. And we never want to feel forced into taking on debt!

Ironic that we purchased Zephyr exactly 2 years ago this past weekend, and we count ourselves absolutely blessed that Zephyr has given us mostly trouble free roaming up until now.

It should be obvious to all – we’re insanely happy with her overall.

However, there’s always been a lingering concern that we just don’t know what’s inside her engine. Sure, we’ve done lots of preventive maintenance to feed good stuff into her and treat her right. But she had sat still for nearly 15 years in the Arizona heat and dust.

This is our home, we desire her to be as reliable as possible so we can focus more on life. And just like any home, repairs come up. We consider this on par with a roof replacement on a regular house – just stuff you have to do every so often, and sometimes not when you hoped for or planned.

But we knew upfront that just because we got the bus cheap, keeping a bus safely on the road is not always so.

Here are the options that we considered when faced with the level of damage we fear our engine has suffered, and how we evaluated each:

Option 1: Repair

The symptoms indicate a range of potential damage lurking inside – a busted blower, a cracked head (or two), blown seals, damaged cylinder liners, bent injectors, or more.

There’s even some possibility the damage is as severe as a cracked engine block.

If the damage is on the lighter end of things, there is a chance that the engine could be patched up in place – without needing to take it out. We could be back on the road within a week.

But….

If more damage is revealed – it is a lot easier to diagnose and fix if the engine is out of the engine bay. There is only so much that you can get at while the engine is stuffed up inside the back of a bus.

Also, without diving deep into the engine – any fixes will essentially be just band-aides. The real state of the engine will remain a mystery, and we’ll always be left wondering what the next part to fail might be.

Given the symptoms, we want to be darn sure that everything damaged is fixed – not just patched and punted down the road. And given that the history of the engine is a mystery to us, if we’re taking it part way apart – me might as well go over everything.

So for us, just patching her up as quickly and cheaply as possible wasn’t something we were keen on. We have the time and funds to do what we always intended to eventually do anyway – get the engine refreshed, renewed and as reliable as possible.

We took some heat in the bus community for not pressing for more diagnostic of what went wrong and what the full extent of the damage is first before picking a plan of action. But for us, that would be wasted labor hours when we knew the outcome of further diagnostics would be unlikely to change our ultimate plan.

And considering that the rebuild/swap/repower process would likely reveal and correct the cause of the original failure anyway, why waste the effort up front?

Option 2: Replace

A realistic option was simply finding another Detroit Diesel 8V71 engine to swap out for ours.

The Detroit Diesel 71-series engines were first manufactured in 1938, and the 8V71 configuration came to market in 1957, and remained in production until 1995 (and is still being manufactured for military applications).

It is a true classic piece of awesome engineering.

Even though there are no “new” engines being built anymore, with a production run of nearly 40 years there are still plenty of engines to be found.

The options we’d be able to acquire for a full replacement would fall into one of these categories:

- Take-Out – When word got out about our breakdown, we learned of several engines offered for sale from other fellow bus nuts. People let us know they were willing to part with a spare engine they were keeping for their own rainy day, or the engine right out of the project bus that they had given up on. Even factoring in shipping, going this route would be the most affordable way to get a new-to-us engine, priced in the $2-5k range. But, unless the engine had been recently rebuilt – we would be no further ahead than we were before we overheated. We’d have an engine that was reported to have worked that last time it was started up (perhaps 10+ years ago), but we would be taking a gamble on the future level of reliability. It just wasn’t worth the potential savings to go through the logistics (and time spent waiting!) of having a potential mystery engine shipped our way.

- Rebuilt – Rebuilding a big diesel engine is commonly done in service shops as part of regular maintenance (perhaps every 250k miles), and it can even be done “In Frame” without removing the engine from the vehicle, or “Out Of Frame” for a more thorough and complete job. Engines with a recent documented rebuilds can be found for sale ready to go – and depending on the state of the engine they started with and the skill of the shop that did the rebuild you can end up with something very solid and reliable. We were finding prices in the $6-9k range for engines with a known rebuild history.

- Remanufactuered – There are factories out there that specialize in fully disassembling old engines and then rebuilding them from parts to exacting original specifications. These engines are fully tested and warrantied, fully cleaned and shiny, and are considered pretty much as good as new. We got quotes for a remanufactured 8V71 in the $11-15k range, with a waiting period of a 1-6 weeks.

- ‘reliabilt’ – MTU, the German company that bought Detroit Diesel a few years ago, also fully remanufactures engines back to their original specs under the ‘reliabilt’ brand name. This would be buying an as new as you can get engine direct from the manufactuter. We were quoted about $19k for one of these, with a 6-8 week waiting period since they are now made to order. It’s also possible we could have tracked one down sitting in a shop somewhere as a spare if we hunted long enough.

Though we quickly dismissed the idea of getting a mystery take-out, we seriously contemplated a rebuilt or remanufactured engine to swap for ours. We would also have the labor cost of having our non-working engine taken out, and the new one put in – in addition to the cost of procuring an engine.

But considering the potential multi-week wait for an engine configured to the specs of an old GM bus, and considering that the Detroit Diesel dealership we were at had the skill to rebuild our own engine to factory-new condition (even including freshly painting it), it seemed like we wouldn’t gain much ordering an engine in.

Option 3: Repower

If we are going to be taking our old engine out, and are considering replacing it, why not replace it with something better?

Changing the type of engine in a bus is called “repowering” it, and this is how our friends Ben & Karen have managed to put a modern Cummins engine into their Creative Cruiser vintage bus, turning it into a extremely fuel efficient rocket.

But repowering a bus can require some tricky custom engineering, and this is especially tricky on vintage GM buses like ours.

The engine bay in a GM 4106 was specially designed by GM and Greyhound to maximize the interior space of the bus to fit as many fare paying passengers as possible. As a conversion, this gives the 4106 a couple extra feet of interior space compared to some other similar bus models, and folks are always amazed that our bus is only 35′ long when they walk inside.

GM achieved this by mounting the 8v71 in sideways in the back of the bus, and using a “V Drive” transmission to take the power coming out the side of the engine and send it forward at an angle to the rear wheels. This makes for an extremely compact and space efficient engine bay. It is an ingenious design. The engine is even tilted at an angle, making it relatively easy to work on right from the back hatch.

Most other buses (and trucks) are configured as a “T Drive” with the engine putting power straight out the front, to the transmission, to the wheels.

V-drive transmissions are exceedingly rare – the V730 automatic we have in our bus is essentially the only practical option that can be made to work in a 4106. And because of the V-bend in the power-train, the engines in GM buses are actually configured to spin with a left hand rotation, backwards from most engines.

Detroit Diesel two stroke engines can be configured (with a lot of work) to run as either left or right hand rotation, but most other engines are right-rotation only.

Combine all these factors, and what this means is that there are very few options for putting an entirely different engine in to a 4106, and modern 4-stroke diesels are essentially impossible without some crazy custom engineering.

But there are some other Detroit Diesel engines that can be made to fit and mate nicely with a V730 transmission – the popular upgrade choices for the 4106 being the more powerful and turbocharged 6V92TA and 8V71T.

The turbocharged 6V92TA is physically a bit smaller than the 8V71N, and is the most modern of Detroit’s two-stroke bus engines, and the most recent releases of it (early 90’s vintage) are actually computer controlled for slightly increased fuel efficiency and decreased emissions.

The other popular upgrade option is the turbo-charged 8V71T – a turbocharged version of the 8V71N (T = Turbo and N = Naturally Aspirated). This engine requires some advanced origami to fit all the necessary turbo plumbing into the tight space of a 4106 engine bay, but it has been done.

Adding a turbo to a 4106 is an especially lustworthy upgrade – friends tell us it “makes a night and day difference” when driving. The turbo feeds air directly into the diesel engine, giving more power, especially useful going up hills and at altitude where the natural air is thinner.

With a turbo – hill climbs go from being a 10-25mph slog to a 55mph cruise.

If we are going to be spending so much money on our engine, why not look into an upgrade in the process?

In our tracking down parts here, our engine’s serial number indicates that our engine block is actually not the original from 1961, but manufactured in 1973 as a right-rotation turbo 8V71T. At some point the turbo had been removed, and the engine was converted to left rotation for installation into Zephyr.

Since we still have the turbo block, if it’s undamaged that makes converting it back to a 8v71T a tempting, but potentially difficult, option.

We consulted with bus engine guru Don Fairchild down in Bakersfield, CA about potentially doing a repower to either a 8v71T or 6v92TA. He’s highly regarded as the master of repowering, and he actually gets these old engines up to snuff to meet California emission standards.

Talking to Don – we started to get excited about the potential for repowering. He told us he knew of some quality 6V92TA’s for $9,500 – and he was excited about the idea of repowering our bus with either one of those, or by turning our current 8V71N into a T.

We’re not really interested in more vroom to start passing other folks on the road, but being able to climb mountains at elevation traveling faster than 15mph is very appealing.

We started seriously considering having the Billings shop take our engine cradle out and shipping it down to Don to repower for us, and then having him ship a complete package back modified to be easy to install back into our bus by the shop here.

But the challenging part about a repower is often all the “extra” stuff involved in the final integration – and we didn’t like the idea of the project being split between two shops.

But then we began to get excited about the possibility of hauling the entire bus down to Bakersfield so that we could tackle the entire project hand-in-hand with Don. Summer in Bakersfield would be unpleasant, but the end result might be worth it.

Even factoring in the cost of shipping the bus ($3k low bid, $9k high bid!) Don’s initial estimates for a repower were looking to be potentially in the same ballpark as what it would cost to do a basic rebuild in Billings.

But once we got into the nitty gritty details of everything that would need to be modified to support the repower project, the potential worst case costs started growing to a point where the benefits really didn’t balance out for us.

When the potential price point for the entire project started reaching the $40k ballpark, we found we had our limits. It was good to price out the high end option however and keep things in perspective.

But in the end there were just too many unknowns to gamble on shipping Zephyr 1,200 miles.

Option 4: Rebuild

The roller coaster of evaluating options ended up right back where we started – having Interstate PowerSystems do a full rebuild of our engine here in Billings.

A rebuild of an 8V71 engine involves replacing all 8 cylinder kits, bearings, and injectors – and overhauling or replacing the blower and pumps and every other component. It’s a substantial amount of work.

And though it can theoretically be done in any shop by anyone mechanically inclined who can meticulously follow directions, there is an art to it.

When done by an experienced 2-stroke mechanic at a certified shop, like the one we happen to be living at, it’s pretty darn close to getting the engine as close as possible back to original factory specs.

Here at Interstate PowerSystems as part of a rebuild they will actually fully clean and repaint the engine to look new again, dyno test and tune it, and then warranty the engine for a year (warranty good at any Detroit Diesel shop).

It’s a toss up if rebuilding our current engine or swapping it out for a quality replacement is the better choice. In the end, the costs come out similar.

In our case, we had to first confirm we didn’t have an early model 8v71, as the blocks on those apparently aren’t worth rebuilding. But when we discovered our engine was replaced with a 1973 model at some point, and we have the stronger turbo block – this tipped us over the line of deciding ours was worthwhile rebuilding instead of swapping. Also because our bus was run regionally, not nationally, we’re going under an assumption that the engine block might turn out to have less wear on it than perhaps a more heavily used one we might end up with during a full swap.

The two big advantages of doing a rebuild here are that we get to start right away, and that we get to watch and learn from observing the process.

Option 5: Mountain Cabin

And of course there’s always the option of just hauling Zephyr to some nice acreage in the surrounding mountains of Billings, MT and using her as a cabin home. Of course, we might need to get a furnace installed if we hope to survive the -40 degree Montana winters!

Nah. We’re nowhere near ready for getting off the road!

After 5 intense days of research, lots of time on the phone, and a bit of bickering on the bus forums – we came to our decision.

We decided to authorize Interstate PowerSystems here in Billings to remove the engine and start assessing the damage with the intentions to rebuild. If they get in and find minimal damage not necessitating a full rebuild, or too much damage to rebuild at all – we’ll adapt as needed.

In the end, we should end up with a shiny newly painted engine and fully refreshed engine bay. In addition to the engine rebuild, we’re re-coring our radiator from 5 to 7 cores, replacing all hoses, the water pump, thermostats, and adding in additional cooling features to the transmission. When it’s all complete, they’ll put the engine on the dyno for a while and give it a full test out to make sure she’s rock solid.

The estimate for all the work is about 2-3 weeks (a lot of that potentially spent waiting for parts), and the initial estimate is in the $19k range. We expect to face some project creep as we give into temptation to take advantage of the engine being out to try and tackle a few other projects, and to take a closer look at components like the starter and alternator as well.

We get to live onsite in the bus while the work is done, and we’ve been invited to shadow the mechanics and learn. And yup, they know we’re reporting live and some of them have already told us that they’ve been checking out the blog. (Hi!)

If you’re anxious to know more about what is found as we crack open the engine this week, we’re keeping up in more real time on our Facebook Page (it’s a public page, you don’t have to sign your life over to Facebook to lurk). The blog updates, as always, will likely run a couple days behind.

We’ve had to cancel our primary Oregon plans for July (we’ll share more about what might have been later), but we are still keeping the possibility of going to Portland for the World Domination Summit next week.

Right now, we’re thinking we’ll hit the road in the MINI and turn that adventure into a motoring road trip. Hopefully by the time we get back Zephyr will be getting ready to hit the road again.

But no matter how long it takes, we’ll adapt, and take the time to do it right. If you’re passing through Billings, give us a shout!

As long as we are back on the road before the Montana winters come!!!

i know a bit late here.

but what condition is/was the transmission in? worth rebuilding it while the motor is out?

i sometimes look at buying a old bus, but worry about lack of power, bad running gear, and the cost to rebuild it all.

We had it inspected, it was fine.

Hi I have been keeping up with you I also have 1961 pd4106 bus with the 8v71 but I have a four speed trans . I have ask you where to find the vin number on the bus I have looked under the drivers seat but I still have NOT found it .If you or anybody else can help that would be GREAT thanks Lester

It’s in the compartment underneath the driver’s set – etched into the hull.

I reread all you went through in deciding what to do, but I did not see why you decided *not* to add a turbo to your existing engine seeing as how it is already setup to accept a turbo. Was it a cost issue or a engine compartment space issue?

— jcw

Our decision points were fully documented in the Repower section – the high cost due to the hauling, special engineering to fit the compartment and scarcity of parts all rolled together for us.

You guys are just too cool! Love the whole lifestyle you are leading. Just bought the E-Book “No Excuses…”

But we need android apps!

Good Luck to you both.

I don’t RV (yet), but have family who do and I’ve read your blog for years while encouraging them to read it too. Reading this has been fascinating to this geek girl. A great example of why blogs are still so very useful. Looking forward to more in this story.

Thanks for the public FB page link since I have no need for a Facebook account but do want to learn more about your latest adventure.

Sorry my mistake eng, kdu trips a 220

Seems I have. (2) kdu220. (1) T9 sender in my used brass bin yours if needed

Boy am I getting old we would do that job for 3000$$ and still make a boat load $$$ my cost was 1600$$

200$ a hole and 200$ pr, head as needed blocks were 800$

Cams 150$ each crank 500$ all parts in house 4days to marry it all up (along with the rest of my work stuff)

at anyone time I had 2 eng,s siting on the floor redy to go turn a round time was the next day bus don’t make $$$ sitting as a yard queen

Forgot have the shop water test the new or old thermostat with u there

Hay guys

Bad bummer that hill did you in any temp over 210 will trash a GM as you know one bet is the upper head

But seeing as you have a t block u can now use trunk type pistons

Now do this take the thermostat sender out and hot water test it with it hooked up as it would be in the bus I would be looking for a loss in reading at the sender to the dash gage and how much like eng, 210. Gage 205

Safety trips at 210 or 215 it will be stamped on the triping sender

At the same time take the thermostats out (old ones)and hot water test Tham as well I would go so far as testing the new ones as well. Doing this will give u a better understanding about water temps down the road

A water test is easy 1 gal, water bucket with a heater and and dip sender stub end in water a laser gage to test water temp heat water to 210 read water temp at bucket and check reading at gage on dash ( take photo as a reminder)

As a afterthought u might look in to a eng, mister some like it as a back up

Thanks for all the feedback, Mister Ed!

Sorry we broke your bus

So sorry about your trouble. I have been keeping track of the story here and on BCM. I am glad it seems to be coming together for you now. I know the next few weeks will probably be a little of roller coaster emotionally but we will be hanging on with you.

The support and advice you received from the bus community is invaluable. It amazes me that some are so offended if you even hint at not following some advice to the letter.

Glad you are able to shake it off. It makes me a little leery to post over there even though they have been so much help to me. Ouch!

Thanks for hanging out with us Davy!

The BCM experience is a mixed bag for sure… we are getting invaluable advice on board, and off (more off, actually). But indeed the lash back for us not taking some people’s specific advice, when we are balancing the advice of dozens along with our own goals, is a bit.. umm.. troubling. But we can shake it off

For us, the benefits outweigh the concerns.. mostly. And we certainly are hearing from many that they are leery to post over there for the reasons you mention. And that’s not good for the community as a whole.

Cherie …come on…bacon,sausage,eggs,homefries, hush puppies, lots of hot coffee…donuts.. what ever….every morning will keep those boys coming in every morning. Set up a big table and tell em to show up early… Plus… a little motherin’ will go a long way.

Enjoying the process and interested to see cause of problem.

Good luck to you both.

Hah… ‘mothering’. Anyone who knows me would know I didn’t come installed with that gene

Congratulations on your thoughtful, well-considered, sound decision. Plus, I’m totally jealous about being able to shadow a complete (possibly) rebuild. I guess I’m just a geek of a different flavor, huh? You can bet I’ll be checking out FB! Fair winds you guys.

Hey guys, great update! Better to be stuck in MT than Bakersfield. My husband was a diesel mechanic for many years, and here is his input into your decision:

Good decision! But since you are re-coring the radiator and fixing any potential cooling problems that would be required for increasing the horsepower, and since it it a turbo block anyway, why don’t you consider finding the turbo parts you need and turbo-charging your engine? It will save the wear and tear on the mini for pushing the bus up the hill.

And by the way, we feel a small kinship to Zephyr since she is from Yuma, where we have a winter home (still here actually–supposed be be freaking 117 this weekend! Leaving in 2 more weeks…)

In any case, glad things are progressing for you, and all is well–we are also from Oregon and still claim Oregon as our state of residence–used to live in Sisters and our son went to Reed College–so enjoy Portland for us too. We’ll be heading East initially but back West by end of summer.

Thanks Tina… as we described in the re-power section above, we did seriously investigate turbo charging the 8v71. It’s much more complicated than just finding the parts (which are hard to come by), and everything would have to be reconfigured inside. When the price got to $40k, that’s when we decided it wasn’t worth it.

Oh yeah, there’s that little matter of 40K. :-p I’m sure you will continue to make the very best decisions and all will be well!

Really glad you took the time to think things through and made a decision. It is also great that you were ready financially, since so many are not. Hopefully it all goes well and you will have the benefit of trusting your engine while you travel.

Hey Guys,

Just caught the news. Bummer!

I’ve had the head off my 6-71 in The Ghost as well as the timing gear end covers. Every time I take something off, I find something disturbing on the other side! Pieces of broken off air compressor drive material sitting in the end covers, crap in the oil pan, loose bolts, cracked water pump drive; it never ends!

I watch my temp gauge like a hawk and as sound advice from my dad, if she starts climbing past thermostat opening, I pull it over and cool it down. We do the Portland, OR to Burning-Man trip regularly so The Ghost is very familiar with hill climbs and heat.

We do the Portland, OR to Burning-Man trip regularly so The Ghost is very familiar with hill climbs and heat.

Hope everything goes well and take a bunch of photos of the process!

It’s amazing how well these things can run with things amiss, eh?

Hey.. if you hear of any spare BM tickets up for grabs, let us know

I may be able to help you out with that. Email me offline.

*phew* And here I was muttering this morning about taking on replacing the final four windows of our house. Mind you, there’s no outside help at this point, but that’s probably part of why that project wasn’t quite as much of an outlay as your rebuild.

At least you’ve made your decision, and it sounds like it was the right one. Kinda awesome that you had the “newer” block. That helped.

Chill.

Now let’s hope the block is healthy and rebuildable.

Chris, Cherie and Kiki, sorry to hear about the Zephry having a break-down. I have been keeping track of everything here and on the bus forums as you 3 decided on how to heal Zephry. When all is said and done, your love and the (Doctors) mechanicial skills will shortly have Zephry happily taking you all on your continuing adventures. Until she is healed again, have fun as always.

Respectfully, S Kaeseman

Oh Thanks again for keeping us entertained and teaching us so very much.

Thanks for the positive energy… and we are happy others are entertained and learning.

I agree with your decision to rebuild your current engine and I would do as you’re doing and replace all the hoses, water pump, redo the radiator, etc. It will be expensive, but in the long run will pay back every cent by giving you trouble free miles.

I’ve worked on DD 53s and 71s during my career and have found them easy to rebuild and after a rebuild, they are as good, if not better, than new.

Hope everything comes out faster and under budget than originally estimated.

Thanks for the positive energy and reinforcement, Paul! Here’s hoping our rebuild goes as smoothly and troublefree as yours have.

I agree you know how to write well and I’ve learned something reading your blog. Have fun in Billings. Michael in Hamilton, Montana

Thanks Michael! We are happy that others are able to learn a little something from our adventures.

I really like how you took the time and looked at all the options before coming to a decision on what to do. I have a bad habit of just jumping into things without to much thought and most of the time it comes back to bite me. You to got a great set of heads on those shoulders. I have learned so much from you guys and I’ve just recently found y’all. My wife and I are new Nomads going on 3 weeks now. Loving it… Thank you, were learning so much from y’all. PS. Give Kiki a pat for us.

Hey guys.. welcome to the road! Sometimes jumping in works, and sometimes is pays to take a breath and think it through. The trick is trying to determine when each approach makes the most sense.

Looks like you guys made the right decision. Pulling for you that the engine is not torn to shreds and you can button her up as quickly and as painlessly as possible.

Gonna check out your Mobile Internet Handbook now that it’s on iBooks (just copped a new iPad mini last week!)

Thanks for checking out the book!

Wow! You sure like to write. Lucky I like to read.

We’re following your adventure. Hang in there.

The Geeks.

Thanks guys… hope your rally went well!