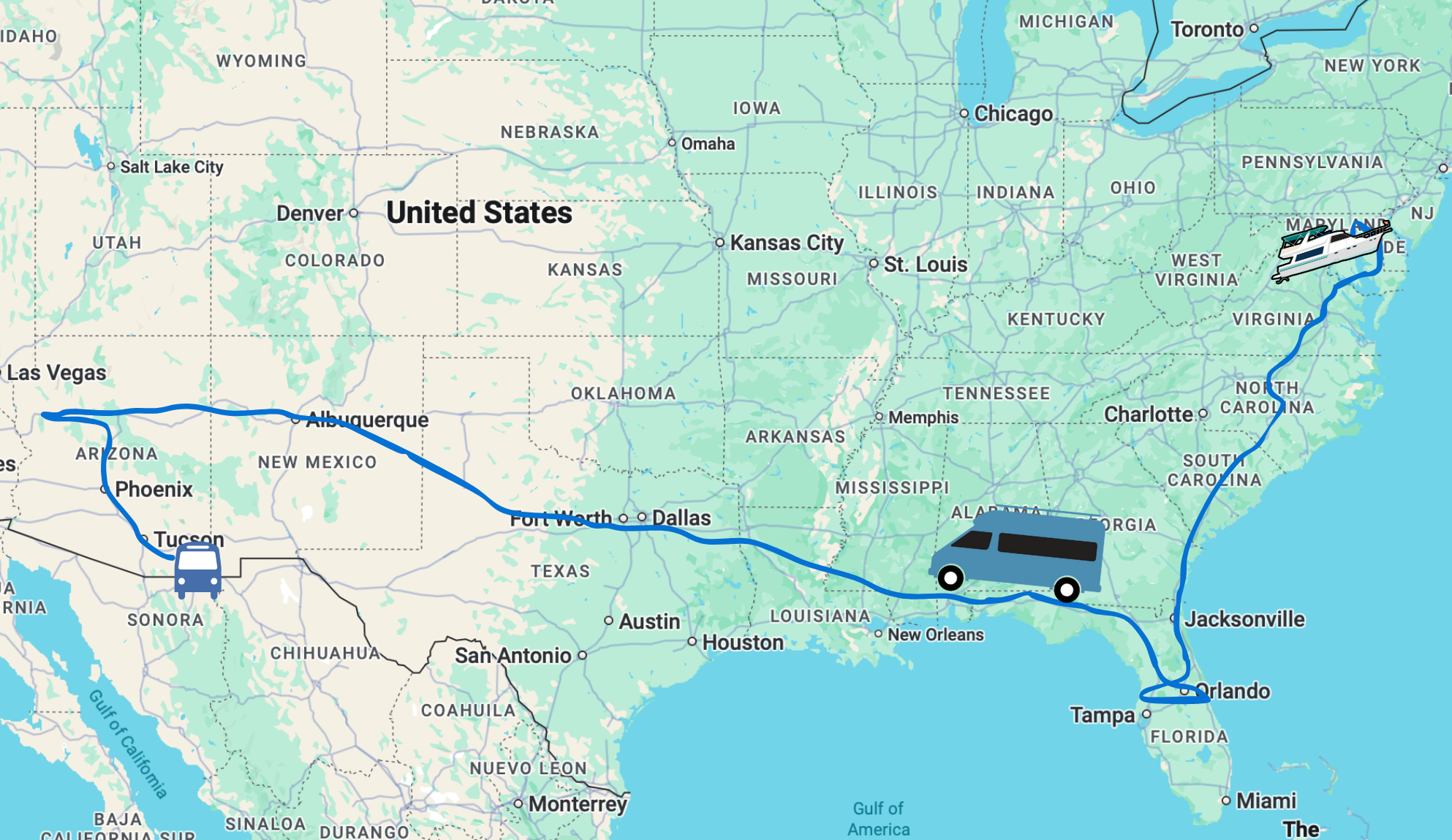

What to do with a broken down 40 year old Detroit Diesel engine?

After pondering our options, we decided to give Interstate PowerSystems the go-ahead to pull Zephyr’s engine for a full dissection with intention to rebuild. We had grown comfortable with their expertise, openness, and professionalism – and felt that they were the right shop for the job.

”We can rebuild it. We have the technology. We can make it better than it was. Better…stronger…faster.” – The Six Million Dollar

ManBus

But first we had to extract the engine from the bus…

Old time bus mechanics have told us how ‘back in the day’, a revenue generating bus shop could swap an engine out of a 4106 bus before lunch, and then do another in the afternoon. The entire engine cradle is attached to the bus by just four bolts (and a whole lot of hoses and wires!), and two technicians who knew exactly what they were doing could unhook the old engine, lower it onto a cart, and roll a ready replacement right in without even breaking a sweat.

Old time bus mechanics have told us how ‘back in the day’, a revenue generating bus shop could swap an engine out of a 4106 bus before lunch, and then do another in the afternoon. The entire engine cradle is attached to the bus by just four bolts (and a whole lot of hoses and wires!), and two technicians who knew exactly what they were doing could unhook the old engine, lower it onto a cart, and roll a ready replacement right in without even breaking a sweat.

Doing the same procedure on a bus that hasn’t been wrenched on in decades wasn’t quite so painless – but it still took well less than a day’s work to perform the extraction.

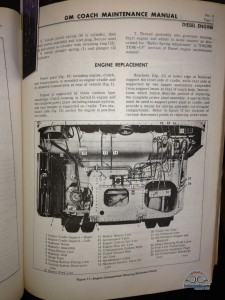

Anthony, the Interstate tech assigned to the disassembly, fought with old fittings that hadn’t been loosened in decades, and used colored wires to carefully mark every hose and wire for eventual reassembly. A few bolts needed to be cut away. None of us had first-hand experience disassembling a GM, but our original GM manual proved invaluable to help track down a few tricky details – such as realizing that the bumper came off as part of the engine cradle, and did not need to be removed separately.

Not having a GM4106 engine cart to drop the engine into and roll away, we made do with a forklift. A very big forklift!

And by late that afternoon, the engine was out!

Once extraction was complete, we dragged Zephyr back out to the parking lot for an extended stay, now complete with a back sun porch.

The engine meanwhile got treated to a spa day, steaming the accumulated decades of gunk off.

And then the disassembly began.

The past week has been hugely educational seeing our big engine stripped down piece by piece to just a bare block, relatively tiny in comparison. The tech responsible, Steve, has been fabulously meticulous – and he knows his way intimately around a 2-stroke.

First the Allison V730 transmission was separated and set aside.

Then the engine was hoisted from the fork lift and mounted on a stand

Then all the accessories mounted were removed – one at a time we watched the starter, alternator, blower, water pump, exhaust manifolds, oil pan, oil pump, and air compressor come off. The cylinder heads were carefully removed and set aside, in the process exposing the mechanics of the Jake brake, the engine timing ‘rack’, and the N70 injectors which spray the diesel into the cylinder.

Removing the cylinder sleeves and the pistons revealed signs of extreme heating (and even cracked liners) – but the heat damage was evident primarily on just the two centermost lower cylinders.

With the pistons removed, the engine could be flipped over so that the crankshaft could be inspected and removed for magna-fluxing and polishing.

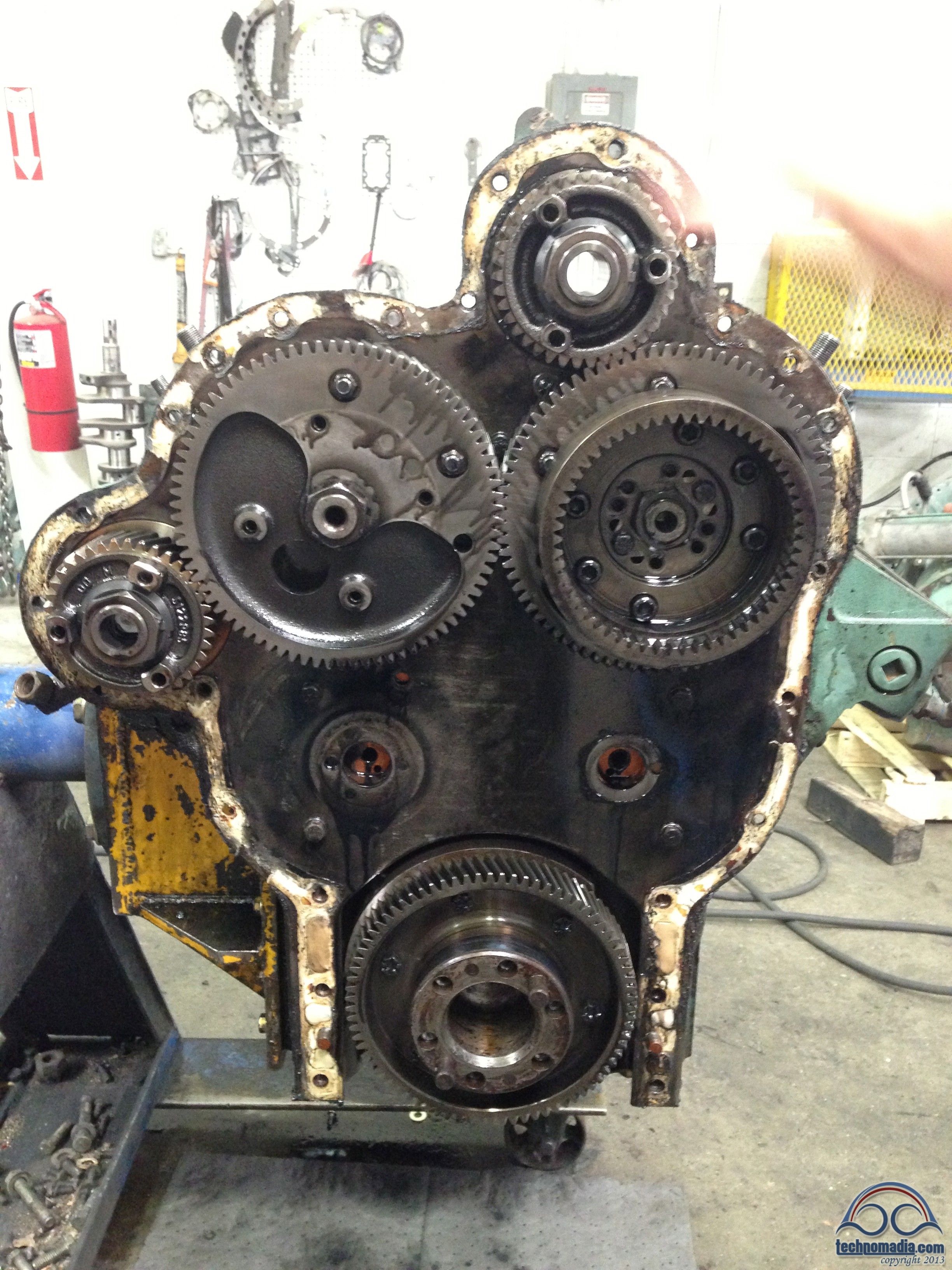

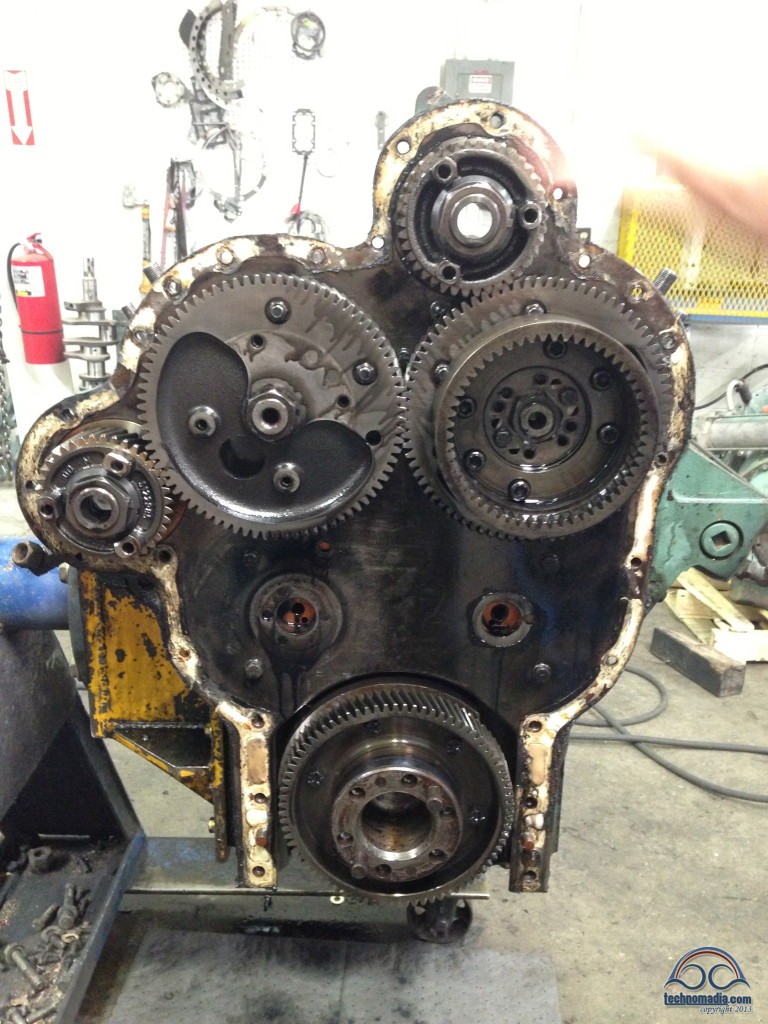

Then the beautiful watch-like gearing at either end of the block could be extracted, and the two camshafts removed as well.

Finally – we were left with a bare block. Steve put it through an industrial washing machine, and has been cleaning, polishing, and inspecting every square inch of it to prepare it for rebuilding – working out the parts list of every little thing that needs to be rebuilt or replaced to make our engine as good as new.

It was an absolutely fascinating process, and we loved that the our rebuild tech Steve took the time to answer all of our questions and explain the inner-workings of every part of the engine.

This video slideshow gives you a taste of it all:

What we learned about what went wrong:

The goal of the disassembling the engine wasn’t just to prepare it for rebuilding, but to hopefully determine exactly what might have caused the problem in the first place… and repair anything that might have been our next awaiting problem.

We were able to rule out theories like the water pump spindle breaking, stopping coolant circulation. And the thermostats were a tiny bit crusty, but have tested as still functional and not sticking.

The things we discovered out of the ordinary during the dissection:

The air filter (less than a year old and with just 4,062 miles on it) had blown out, and was partially sucked into the engine air intake.

The air filter (less than a year old and with just 4,062 miles on it) had blown out, and was partially sucked into the engine air intake.- The two center cylinder liners on the lower bank showed signs of extreme heat and metal fatigue.

- The coolant hose to the air compressor was completely clogged – seemingly unrelated to the current issues (the air compressor was working fine), but discovering this and fixing it will save us from an air compressor failure someday down the road.

- The shaft for the oil pump was starting to wear out. It was far from failing, but catching this now saves us a major eventual problem. Finding these lurking future issues is exactly why we wanted to do a complete out of frame rebuild and not just the quickest possible repair.

Everything else inside the engine so far looks to be in good shape, other than typical wear-and-tear and age. So as of yet, we have not reached a definitive conclusions as to what malfunctioned to cause the overheat situation and damage in the first place.

All of the technicians here feel confident that the block is serviceable and a good foundation to rebuild on, and we’re rebuilding or replacing whatever else we can as preventive action.

What next….

We’ve been given a firm quote for the work, which came in less painful than anticipated… and now the rebuilding begins.

The alternator and starter have been sent out for overhaul, a new radiator core is being constructed complete with a new transmission cooler, and all the necessary engine parts have been ordered. All other pieces serving the engine are also being carefully inspected, cleaned and rebuilt/replaced as needed – from hoses, wiring, pumps, thermostats and more.

We’ll be installing remanufactured and warrantied heads, instead of cleaning up, testing and rebuilding the existing ones that may or may not have suffered damage in the overheat.

This coming week, we look forward to seeing it all going back together – a piece at a time.

A work of art. A jigsaw puzzle.

It will be fun to watch and learn. *grin*

Such a wonderful work!! I’ll like to know more about how you guys change the sensors and valves, been struggling with speed sensor

Oh gosh.. this post is almost 15 years old. Highly recommend finding Bus Grease Monkey on Youtube, he has lots of Detroit Diesel videos.

Hi … I had no idea about your blog ’til Brian Evans’ post (Reply #7) on busnut.com (http://busnut.com/forum/index.php?topic=1481.0) alerted me … I shall dig in to your content over the coming days … I can see many topics of interest in my pursuit of my marine cruising up here in the PNW … of particular interest to me at the moment is a document (“a very good description and diagrams of how injectors work”) he shared with you folks (on or about 03AUG2013) and says was posted to your site – I cannot seem to zero in on it … is it still on your site? Thanks, Kevin Mc

Welcome to the blog.. I don’t recall us ever posting about how injectors work. Wouldn’t be the sort of thing we’d cover (out of our expertise).

Hello I saw you guys talking about a diesel engine 8va71 can you show me more on it

This series of posts is all we have to offer. But would recommend checking out the Bus Grease Monkey YouTube channel, he has an abundance of content. https://www.youtube.com/@BusGreaseMonkey

Very cool, love the sound of those old 2 stroke Detroit! They where the work horse of a bye gone era!

Good stuff. Educational instead of the usual misinformation all over the net about Detroits. Thank you.

Detroit Diesel was a good customer of mine for years and I spent a lot of time in the plant. I enjoyed the engine assembly lines, the dyno rooms, and the custom engine paint and dress area. Also, I have a boat with twin 8V71TI’s. I used to have the DDAD engineers out on the boat and had good times with that. They liked to sit in the engine room between the engines while running at speed.

Love those Detroits, nothing else like them!

I have a pair in boat and love them. Enjoy the bus. It is soooo much easier to work on them on land. I honestly have no idea how to get large blocks/parts on/off the boat.

How far Have I gotten on tHe engine? I hope it’s coming together real well.

It’s all being live blogged on our Facebook page, complete with photos. http://www.facebook.com/technomadia

Wow…discovered your website and videos recently and have learned so much. After almost 44 years of marriage, kids, jobs, and all that includes, Hubby and I are studying and thinking about making the switch to rv living. Your website has been very helpful and informative as well as fun. The info on your engine work is amazing (and even a little scary) but your REAL view of life on the road is helping us tremendously. Keep up the good work, can’t wait to see you back on the road again.

thanks to al ( Al there a (alt,)gear on (cam)gear setup (Al see photos 4the big green thingy on the photos right side see photo 5 with open hole that bad boy is about 35/40 lb(only one size) i all most forgot your at a truck shop truck alternator dont hang off the back

chris show tham your book for an alternator alignment tool setup ( it alig,s the female alt,gear to the bellhousing witch in turn keeps the male alt, gear from binding up on the cam gear

by the way would u see if u can steal the cinnamon roll recipes from Ms Terry Bad Nick gets his fingers on it theres none for me.. thats ok.. im going to have his credit card stopped at Dixie Crossroad in tutusville joy your day

Some time ago, when you were doing some electrical work on a battery system, you mentioned the alternator output was too low. There was some comment about the engine rpm being too low to drive the alternator to full output. You might want to look into changing the alternator drive gears to a different ratio to get the alternator speed up a little higher.

Al

I hope everything goes well with the mechanics and see you on the road very soon.

Good luck

J.K.IversjÁ¶

Nothing really I can add to this except WOW…horrible that you’re shut down and off the road, but ULTRA cool to see the rebuild. Amazing stuff.

Nina

Great post. Thanks for sharing with us. I am enjoying your adventures. Kendra and I will be starting our adventures later this year as we are now retired and looking for our Dynasty.

Nothing better than driving a vehicle where you’ve been a part of rebuilding the engine. You have a relationship and knowledge you just can’t get any other way. What a great shop that is to let you stand by their side — most would shoo you out to the customer lounge.

I’m hoping my wife will never see this. I’ve told her we’re buying a bus because they never break down.

thanks but your in good hands

well if u can take any one oil bath can out with out spilling it good luck

thats y most change it out

i think u had 3 or 4 cans up there

do u think u can get a filter to fit a higher CFM than 1000 1600 would be nice,,higher CFM filter will not stop it from starving but the CFM restriction will max out at 1600 not 1000

pick a name brand and by the way how high was your elevation

well this guys going to the beach(cocoa beach) that is to study wave-height and Bikini-ology joy your day

I’m still hung up on you being able to put “porn” and “stroke” in the same paragraph! OK, now that I’ve got that out of my system, I’ll go back and read what you actually had to say. Let’s just hope though, that the whole ordeal is CONSIDERABLY less than six million…

*giggle* Thanks! Glad someone appreciated it 🙂

Nicely done and very entertaining story. Enjoyed the read.

Sorry for mistakes in english, I’m using Google translator.

My name is Jorge Luiz Pigat Zuchowski, I live in Brazil, in the city of FlorianÁ³polis, state of Santa Catarina.

I would like to congratulate them for free lifestyle, living in a motor home.

I’m also lover of motor home and am starting to rv conversion.

My bus is a Scania chassis bodied BR-116, Dinosaur II, inspired by the GM PD-4104 which had been imported from the United States.

See my blog: http://PangareSonhador.blogspot.com.br

I am following their nomadic life and wishing good luck.

Jorge – pp5yy@ymail.com

Jorge – How exciting to have you stop by our blog! Thank you! I enjoyed looking at all of the pictures of your Scania and your in-line 6-71.. and you have it Turbo’d?? How awesome!!

Good luck with your conversion, and hope that we can perhaps meet up somewhere in between the USA and Brazil!!

Hello Cherie and Chis, thanks for the reply.

Yes my Scania has turbo. My bus is the year 1981 and the model is Scania DS11 engine with 296 HP of power. Before riding with my Motor Home I had to refurbish the engine, for lack of care in maintenance performed by the previous owner.

I want to see them soon on the road to new adventures.

Maybe one day we met in person, here in Brazil or the United States.

A big hug.

Hi guys that first post foto is great when u brake down O well one makes do

I’m like a kid at the candy shop at the glass door chomping

At the bit to get in,, buy the guy a cup of coffee for me, one thing the air filter was it new or a re wash

And is it sized to take the intake air flow I never switch GM,s over from oil to paper on any coach all our new MCI,s came setup paper

Did u fix ur a/c

Joy your day

the 8V71 requires 875CFM, the 8V71T requires 1250 CFM. is your air filter a donaldson

The filter that failed was a Baldwin, rated at 1000 CFM.

Mister Ed… I can set up a livestream video feed into the shop if you want?? It’d be almost as good as being here.. Be in touch, I’d be happy to set it up!

We’ve told all of our techs about you, and they are so impressed and touched that you’re following long! I know they’d *love* to have a cup of coffee with you and meet Zephyr’s mechanic when she was in service!

The filter was brand new, 1000 CFM. And from what we’ve learned.. it’s shame that someone along the way, after you, converted away from the oil filter.

You’re doing a great job of showing this rebuild step-by-step. I’ve worked on DDs in my past career and you can see the craftsmanship in what your techs are doing.

I think it’s a good call to get the remanufactured heads, too. One (two) less item(s) to take up time on the rebuild.

Your “back porch” looks nice but don’t get too attached to it. We want to see your engine back in place soon! :c)

It turned out that the cost of testing and rebuilding our old heads wouldn’t have worked out much cheaper than getting remanufactured heads, and the remanufactured heads will come with a full warranty.

Even better… They opened the first of our remanufactured heads today, and it actually appears to be a brand new cast – never used in the past at all.

Score!

– Chris

I love the project (though not what caused it). One question, though. With those two cylinders, do they think that the damage could have been caused long ago and just accumulated to a “breaking point” (no pun intended). And, I think that you will have an engine and engine bay that are better than new. They may have done quick swaps, but neatness would have taken a back seat to getting the bus back on the road.

Dave – I personally have seen the now-closed Greyhound HD shop in San Francisco do the V-drive powertrain swaps, which is what I believe Chris/Cherie was referring to at the beginning of this blog post. Two technicians, one bus in the morning, one bus after lunch. They didn’t “steam clean” the engine compartment, but the pre-built replacement powertrain assembly looked just like the day it came out of the factory – except ‘Hound painted their rebuilds red!

It would take the same two techs all day to do a T-drive powertrain swap in a Scenicruiser or MCI.

Back in those days, Greyhound was the envy of the transportation industry for their maintenance program. Alas, that all went away once the hot dog salesman took over corporate. . .

Yup the 8V71 was a very popular marine powerplant in its day. Speaks well for the design. Wish I had a couple in a boat. 🙂

It’s a timeless design.. been around a long time in many applications. One reason we’re so keen on learning it is our eventual dreams of water-life, and knowing that it’s a frequent powerplant for many vessels.

As always your blog is interesting and I’ve learned something useful. If my 92 Cady engine goes south I will find someone to rebuild it. It now has 195,000 miles on it. Cheers, Michael

That’s a lot of miles.. hope it keeps you on the road for a long time to come!

One of the great things about these industrial-sized engines is that they are engineered to be completely overhauled and rebuilt many times in their life. I don’t think many car engine blocks are nearly as rebuildable – it may be better just to start with a new engine / block.

I have a pair of 1979 8v71TTI in my boat and love the simplicity of them compared to the newer computer controlled one’s.

So I am very interested in this process.

Bill Kelleher

The simplicity of these engines, combined with the sheer power they produce.. is awe inspiring, and art. I so want to transport back in time and poke inside the heads of the engineers who came up with these ideas. Internal combustion is really a singularity in the progression of our society.

The truth is out – the geeks are also gearheads – it comes through in your description of “the beautiful watch-like gearing.” So glad to see your approach to this – you’ll have the engine and accessories as good as you can get them. BTW, it’s nice to see your battery system paying dividends!

We find beauty in a lot of things.. gearhead is just a flavor of geek, after all 🙂 We have definitely been bitten by the 2-stroke bug, and are falling more and more in love with our power systems.

Chris didn’t even mention the intoxicating smell of the inside of our engine. OMG.. can I bottle that as a fragrance???

Hoping that you’ll be keeping this beast Alpine Green?

…you know what they say…if you painted a brick Alpine Green it would leak oil 😉

Hahaha.. true indeed. And yes, they will be painting everything back to alpine green when they are done 🙂 It’ll be shiny. For an hour at least. And we’ll eat dinner off it.

Any thoughts on adding soundproofing to the engine compartment while the engine/trans assembly is out?

Honestly.. we can’t think of much of a need for this? When underway, most the sound we hear is wind noise from upfront.. and we really really dig the sound of a 2-stroke.

We don’t need more soundproofing towards the interior – but I wonder if a layer of matting on the inside of the back hatch might make our engine a bit quieter in parking lots and campgrounds as we drive through? Hmmm….

But that can be added at any time too.

GREAT photos! I especially love the one showing the gears.

Aren’t they awesome?? I’ve been in total lust for weeks seeing all these parts and gears. I about gasped when these gears where revealed. It’s art. Plain and simple.

I think those pictures are pure works of art! What a thing of beauty that engine is on the inside. Almost makes me wish I had been a boy, loved mechanic and had even know what a diesel engine was in 1959. 🙂

Barbara

No reason one has to be male to appreciate mechanics… I’m loving getting inside this thing too, and learning so much!

Very true. Back in the 70’s I used to date a young lady that was one of the best mechanics I ever saw and down right sexy in her coveralls. In a garage she was an artist and put most of the guys I knew to shame.

It is telling though that the only women’s restroom in the shop is the one up front in the office area though. I somehow suspect they’ve never had a female mechanic working here…

Let me start by saying that I am NOT a “gearhead”, but that was very fascinating and informative. I am glad to see that you aren’t taking the easy was out, but instead taking your time and making sure that you will be able to spend many more years (?!) on the road safely! It’s very interesting and a lot of fun to follow your travels! Be safe!

This whole experience is just super amazing.. and wonderful addition to our adventures!

I don’t think I fully appreciated just how big it was till I saw that photo with Cherie. It’s humongous! (Logically, I knew it had to be…but wow!)

Or I’m super tiny?? 🙂

It’s amazing to see it all out in full 3-D. And stripped down to the block.