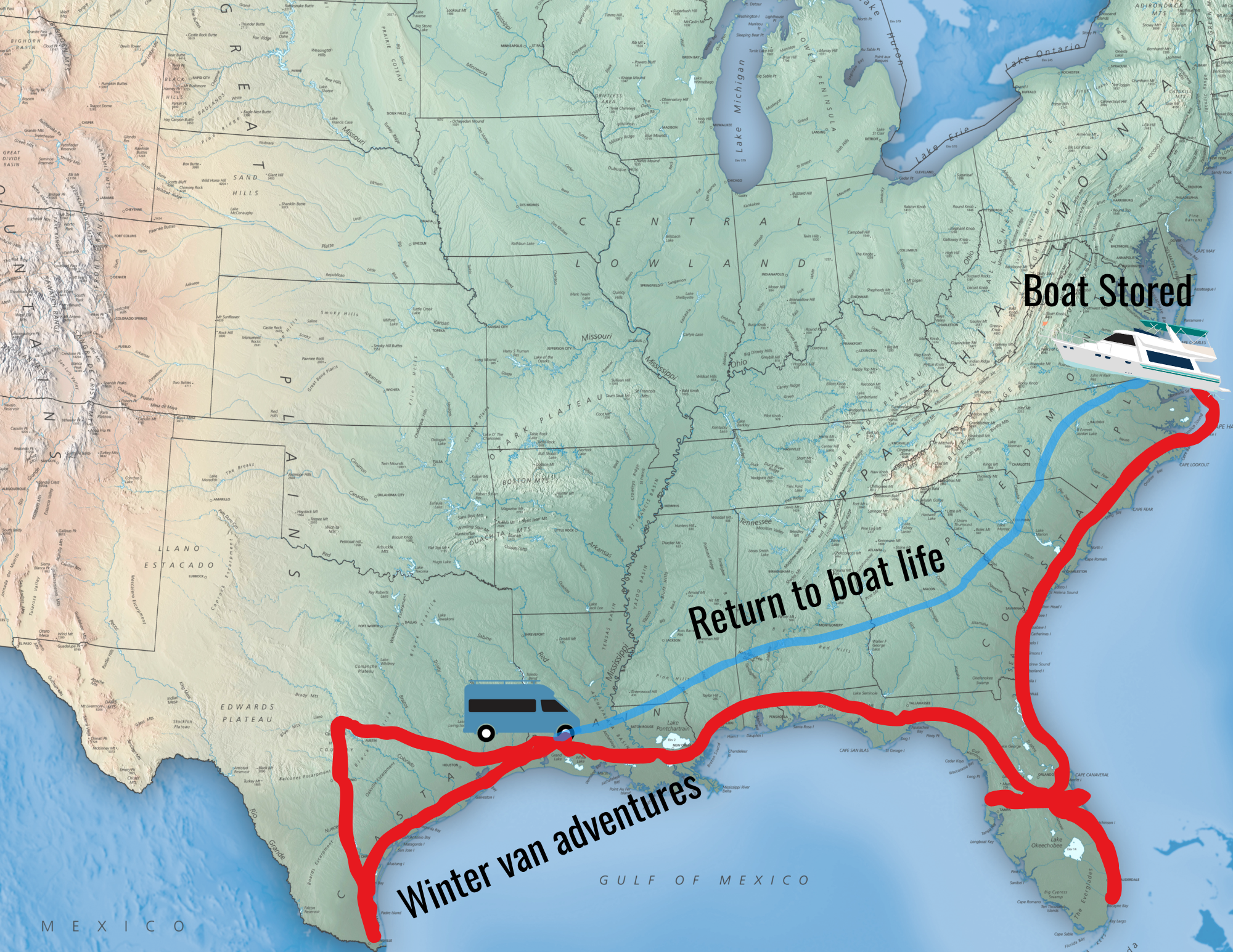

One of the most unusual frequently asked questions we get asked out on the road:

“How’s your lithium batteries working out?”

We’ve even had strangers come up to ask, occasionally without even saying hi first!

But I get the curiosity.

That we are using lithium batteries for our RV house battery bank is one of the more unique things about our already very unique home on wheels.

When we set out to build a 500Ah LFP lithium battery bank 3.5 years ago, we knew we were heading into relatively uncharted territory where only a few had dared to venture before us.

But since the theoretical advantages of lithium batteries in an RV are undeniable, it is only natural that everyone with any interest in RV electrical systems wants to know just how well theory and reality have meshed for us.

People often tell us that they are even holding off on replacing their own aging lead batteries – waiting to hear from us that lithium is at last ready for the mainstream. (No pressure… *grin*)

- After 3.5 years of use, has lithium lived up to all the promises?

- What have been the downsides? Would we do it again? Was it worth the cost?

- And for those wanting to follow in our footsteps, everyone always asks where they should start?

Read on for our ever-evolving thoughts…

Lithium for RVers – A Quick Recap

Way back in 2011 we shared our research and wrote extensive posts about the disadvantages of lead acid batteries and the inherent advantages of lithium – in particular the lithium iron phosphate (aka LiFePO4 or LFP) cells that were just then becoming practical and (relatively) affordable in the sizes required to build a reasonable RV house bank:

Way back in 2011 we shared our research and wrote extensive posts about the disadvantages of lead acid batteries and the inherent advantages of lithium – in particular the lithium iron phosphate (aka LiFePO4 or LFP) cells that were just then becoming practical and (relatively) affordable in the sizes required to build a reasonable RV house bank:

“As you will soon see, on paper lithium ion batteries seem to be superior in almost every possible way — as if Zeus himself had climbed down from Olympus and handed the world the perfect battery. Or maybe it wasn’t Zeus, but that annoying pink Energizer Bunny, bringing the gift of divine electrons pulsing to the rhythm of his eternal drum.”

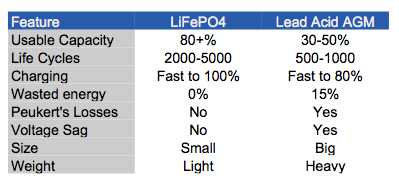

The advantages of lithium over lead are many, but to recap a few of the highlights:

- Superior “Useable” Capacity – It is generally considered smart to treat lead batteries as if they have a useable capacity of only 50% of the actual rated capacity. Lithium batteries on the other hand can be regularly drained 80%, or more.

- Extended Cycle Life – Theory (and lab tests) say that you should expect to get somewhere between 2x – 10x the number of useable cycles out of a lithium battery as you do from even a premium lead battery. If LFP batteries can outlast conventional batteries, this turns into a lifetime cost advantage over AGM despite increased upfront costs.

- Fast & Efficient Charging – Lithium batteries can be “fast” bulk charged to nearly 100% of capacity. Lead batteries on the other hand require a slow absorption phase to get the final 20% of the battery charged.

- High Current Happiness – Due to a phenomenon known as Peukert’s Law, lead batteries drain at an accelerated rate when powering high current loads (like microwaves and air conditioners and induction cooktops) – sacrificing as much as 40% of their capacity in the process. Lithium batteries on the other hand can handle high current charging and discharging without breaking a sweat.

- Smaller & Lighter – A rough rule of thumb is that for a given amount of usable battery capacity, a lithium battery bank will end up being less than half the physical size and just a quarter of the weight of lead.

Clearly – the theoretical advantages are huge.

But the advantage of conventional quality name-brand AGM lead batteries can’t be denied either. Not only are the upfront costs cheaper, AGM batteries are tried and true well established technology with no unknowns and little potential for surprises.

(But, what kind of fun is that?)

Lithium: Ideal for Solar & Boondocking

Where lithium really has the potential to shine is when paired with a solar energy system.

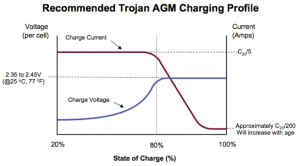

You see – when a lead battery is slowly working through an absorption phase (the downward current slope in the graph to the right) pushing the final 20% of power into the battery, excess energy from solar panels ends up being thrown away as the charging current trails off.

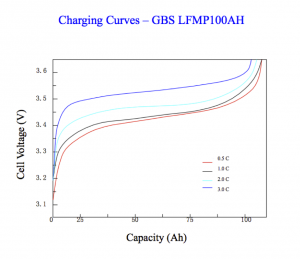

With lithium on the other hand, the batteries can keep taking all the current your solar panels are putting out – right up until they are essentially 100% charged.

And if you have lead, you better hope that you have enough solar panels and daylight to make sure that you regularly make it fully through absorption and manage a full 100% charge – because lead batteries suffer if not regularly topped off.

Lithium batteries on the other hand could care less if you never fully charge them. Ending the day at 50% or 85% charged is no big deal at all. You could go for months without ever getting a full charge and your batteries will be just fine.

The overall charge efficiency of lithium versus lead is better too – meaning that lithium takes better advantage of every ray of sunlight that you are able to harvest.

Even if you don’t have solar and are using a generator to power your boondocking – lead batteries will require hours more generator run time to regularly complete an absorption charge phase. With the faster bulk charging of LFP batteries, your generator usage can be kept to a minimum.

Your neighbors will thank you.

This winter we have been living primarily on solar and wanting maximum electrical efficiency, and we are especially loving the advantages of our lithium battery bank.

In general, we’ve loved just about everything about our batteries – and they have exceeded most of our expectations.

Except in one very important way…

The Dark Cloud: Premature Battery Aging?

When I wrote about the advantages of lithium batteries, I said:

“Laboratory results indicate that you could expect to see 2,000 to 5,000 cycles out of a well cared for LiFePO4 battery bank, which means that a lithium ion battery bank has the potential to likely outlast your RV! These are theoretical results — we are looking forward to seeing how lithiums do in reality for RV use, as the energy uses of a home-on-wheels is not normal laboratory conditions, nor at all similar to that of an electric vehicle (which is where LFP is primarily used right now).”

So how well have our batteries aged?

When our 500AH batteries were a year old (August 2012), I was able to drain 442Ah from them before having the EMS trigger a low-battery alarm cutoff.

When they were nearing 2.5 years old (November 2013) I was able to drain 409Ah before the system shut down.

Last month (December 2014), during my most recent drain test, I was only able to drain 378Ah before cutting out.

In other words – our batteries seem to be aging way faster than they should – now giving us just 75% of their original rated capacity.

Why? What could be going wrong?

Ah – the joys of being a pioneer!

“In theory there is no difference between theory and practice; in practice there is.”

We have a few theories as to what could have impacted our batteries.

January 2016 Update: After making adjustments to our setup described below, we seem to have caught the curve. Our most recent max discharge was 382Ah. So we’re not continuing to see a drop in capacity a year later.

Suspect #1: Temperature

According to the specifications for GBS-LFMP100AHX cells published on the Elite Power Solutions website, our battery cells are rated for:

Operating Temperature: -20C to 65C or -4F to 149F.

But while brainstorming potential causes for our diminished capacity recently, Elite let me know that in their experience heat has a huge impact – even within that operating range.

They have observed that a 10C (18F) temperature increase over a baseline room temperature of ~23C (74F) results in the number of lifetime cycles being cut in half.

This means at 33C (91F) usable battery life will be cut in half, and presumably to a quarter at 43C (109F). This is VERY substantial.

I am disappointed that the impact of temperature on GBS cells does not seem to be documented and published online anywhere (though I don’t feel it was intentionally hid either) – especially considering 110F is actually a rather common summer temperature in Phoenix Arizona where Elite is located!

Had we known this potential impact upfront, we would have definitely approached the installation differently.

Our batteries originally were in a small chamber along with the inverter / charger – and that chamber could get significantly warm when the inverter was working hard powering the roof AC for extended periods.

It never got anywhere close to the 150 degree high-temperature EMS alarm and peak temperature specced for the batteries, but I am beginning to suspect that over the years there might have been enough high-temperature time to have had an impact.

One example – we spent 7-weeks in the summer of 2013 where we were stuck on a hot asphalt parking lot at a diesel shop having our engine rebuilt, and we were depending on the battery bank and our Victron inverter to boost the available wall current to run our AC.

When I rewired the bus last summer I relocated the batteries to a larger and better ventilated rear chamber, so high temperatures are much less likely now.

Another temperature concern is cold – most LFP batteries can be damaged if they are charged while below freezing (discharging is fine – only charging while cold is a problem).

We’ve never had our battery chamber get that cold, but for other people who aren’t able to follow temperate weather this could be a concern.

Elite tells me that they are now recommending RV lithium installs go inside the cabin, such as under a bed or couch, to minimize temperature impact.

Reportedly – one of the secret’s to the battery life achieved by Tesla electric cars is the integrated temperature managements system built into Tesla’s lithium battery banks.

Lesson learned – LFP lab results aren’t taking temperature into account, but RVers absolutely need to.

Suspect #2: Over-Floatation

The final phase of a three stage battery charger is the “float” phase, where the battery is held at a set “float voltage” to keep the battery topped off. In an RV – this float voltage also powers all the DC loads present.

An RV on hookups sits “floating” for days, weeks, or even months at a time.

Lead batteries are generally good with this. Lead batteries love to be charged to 100% full and kept there.

Lithium batteries on the other hand don’t benefit from floating – and in fact evidence is mounting that over time this can actually start to wear on the batteries. For example – an LFP battery is seemingly much happier bouncing between 85%-95% full than being kept pinned at 100% charged.

Just how to best charge and float lithium batteries to maximize battery life remains a widely debated topic (this thread on Cruiser’s Forum currently has 4,246 posts!) – with recommendations varying widely.

But despite a lot of anecdotal reports and experiences shared, most of the actual extended scientific testing of LFP batteries has focused on electrical vehicle applications. Marine and especially RV house battery usage remains a niche within a niche, and advice that applies to a high-voltage high-current never-floating electric car batteries does not necessarily apply to RV usage patterns.

In the past 3.5 years though, the recommended bulk charge and float voltages for RV house lithium banks have been trending downward – sacrificing a tiny amount of peak capacity for a hopeful substantial gain in long-term lifetime.

At the moment I am seeing recommended charge voltages ranging from 13.8V to 14.4V, and float voltages ranging from 13.2V to 13.8V.

We’ve spent the past year using 14.2V bulk charging, and a 13.55V float. I’ll probably soon change to even lower – 14.0V bulk and 13.4V or even 13.2V float.

We’ve dialed back our charge voltages several other times over the years as recommendations have changed, and are still experimenting ourselves. But our higher voltage past may have had an impact, especially when we spent extended periods on full hookups in our first years with lithium.

One trick some lithium pioneers report resorting to is disconnecting their batteries when they are on shore power for an extended period, avoiding any floating risk entirely.

An alternative – a low float voltage of 13.2V should have nearly the same impact as physically disconnecting.

The key here is to make sure your battery chargers are fully programable – especially since few chargers have lithium presets and those that do might be defaulting to higher voltages than you’d life to preserve battery life.

Lessons still being learned – charging and floating isn’t nearly as simple as it seems!

Suspect #3: Lack of Balance / Laggard Cell

Our battery is made up of twenty 100Ah 3.2V LFP cells, bolted together into a single 4×5 slab.

When we built our battery bank, the Elite EMS for monitoring the individual cells did not support cells in parallel, only in series. So to build a 500Ah bank out of 100Ah cells, groups of five cells are hardwired in parallel and a single sense board monitors each of these four groups in series.

This means that we don’t have the granularity to monitor each of the 20 individual cells – so if we have a laggard cell bringing down the whole bank it is very hard to isolate the troublemaker.

The sense boards are also designed to put a slight balance load on the cells to keep them all in sync with each other – but the balance boards 3.5 years ago did not trigger a balance load until the cell voltage reached 3.7V. This is actually slightly above the over-voltage cutoff on the EMS, meaning that our cells effectively never benefit from being auto-balanced.

In the years since – Elite has improved the EMS design to support cells in parallel with every cell having a dedicated sense board. And balancing now happens at 3.55V, low enough to actually have a passive impact while charging – before the alarm kicks in.

If we were building our battery today we would be able to benefit from these improved designs. But from our own observations – even without the active balancing our cells have stayed remarkably well balanced over time.

But still – perhaps this sub-optimal vintage design has had an impact on battery life, or has made it easier for a dud cell to hide out.

Lesson learned – automatic balancing may be important for longevity.

Suspect #4: The Edge Was Bleeding (And Still Is)

When we built our battery bank in 2011, LFP for RV house battery system use was pretty bleeding edge.

Since then cell quality and consistency has improved, and cell chemistry and construction has been enhanced. In theory – if we were to buy the equivalent cells today that we bought 3.5 years ago, they would in actuality perform better.

We’ve come to understand that 3.5 years ago, a 100Ah cell’s capacity was an optimistic rating. Now a 100Ah cell is more conservatively rated – and would actually start off with higher than 100Ah actual measured capacity when new.

This is the nature of technology – things just keep getting better.

The frontier is no longer quite so uncharted – but even today pursuing LFP is not for the faint of heart.

Lesson learned – Nah, no lesson learned. We knew what we were signing up for.

Reality Check

Checking in with experiences others have shared – I see that a lot of other LFP pioneers have noticed similar capacity losses to what we have – across a diverse range of cell manufacturers.

But some others seemingly have managed to put hundreds of heavy cycles over multiple years on their LFP batteries, and are still able to drain over 100% of rated capacity in controlled tests.

We are clearly all still learning the best ways to get the most out of these batteries.

We also have to choose to strike a balance over how much care and careful attention we want to dedicate to our batteries. For the most part – we just use ours without giving them too much thought, and have gotten 3.5 years of great service so far.

If I hadn’t been doing occasional capacity tests, I would not have even noticed that our batteries had prematurely aged.

And we also need to keep in mind – lead batteries rarely live up to their theoretical ideals either under everyday RV usage. We know plenty of people who end up replacing their lead house batteries every year or two, or who are limping by on lead batteries that are more dead than alive.

Contemplating Cost

The Elite Power Solutions 100Ah cells we built our battery bank around still cost the exact same as they did 3.5 years ago when we purchased them – $620 for each 4 pack of cells, or $3100 total to build our 500Ah 12V battery bank.

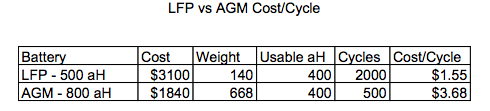

In our initial cost considerations post, we compared our $3100 500Ah lithium battery with the current going rate for 800Ah worth of quality AGM batteries – which we priced out at $1840.

In the years since, lead prices have actually spiked up quite a bit, but at the moment have dropped back down so that the current lead battery pricing isn’t all that different than it was in 2011.

We concluded then:

“There is just no ignoring that a battery bank made up of quality AGM-style lead acid batteries will cost a lot less upfront than a similarly sized lithium battery bank.

But if you consider the lifetime cost, and the fact that lithium batteries should (theoretically) far outlast even the best high-end AGM’s, the math starts to look compelling.”

Considering that our batteries are seemingly not on track to outlive an AGM bank as much as theory promised, our personal value calculation haven’t worked out nearly as well as we had hoped.

Considering that our batteries are seemingly not on track to outlive an AGM bank as much as theory promised, our personal value calculation haven’t worked out nearly as well as we had hoped.

We don’t keep obsessive records – but my best guess is that we have probably logged no more than 500 cycles over the past 3.5 years, and probably way less. Our Victron BMV-702 battery monitor has only logged 56 charge cycles in the past year since we installed it.

But even if we go with a an extreme high-end estimate of 1000 cycles at 50% average DOD over the past 3.5 years, in theory our batteries should barely be getting broken in.

In practice – our battery bank is only giving us 76% of its original rated capacity. That’s not so good.

But our bank is still meeting our typical needs and very likely still has years left before it can’t keep up with our daily use.

Plus we love living with all the rest of the lithium advantages.

So overall while we aren’t likely to see much of a lifetime cost advantage, the cost question is basically a wash for us.

Has It Been Worth It? Any Regrets?

Despite our system not fully living up to our expectations – it has absolutely been worth it to us.

But remember – we (usually) LIKE being on the bleeding edge.

When we initially designed our dream system for our bus, we had hoped to have 1000+ Ah of battery on board. But 3.5 years ago we decided not to invest so much in such an unproven technology, and went with just 500Ah instead.

We’re sure glad we made that decision… 500AH has been a good balance between risk and reward.

If we were starting from scratch today, we would be able to tap into a vast wealth of experience and assistance that just did not exist when we started. Our own knowledge of RV electrical systems has vastly increased too – in large part we have learned by doing as we tackled this project.

Especially considering that solar-powered boondocking has become an increasingly frequent part of our lives, the advantages of lithium remain too compelling to ignore.

So yes – if we could go back in time and advise ourselves to do lithium again, we would.

And we’d pass along a few pointers: Cooler. Less floating. Better balanced.

And if there is a next time – we’d go even bigger. We have discovered that 500Ah is a great size for us, even at our current reduced actual capacity. But having more battery like we originally envisioned will better let us bridge cloudy days and bad weather while still feeling abundant.

We’ve sized our new battery chamber to be ready for a 1200Ah or 1400Ah battery bank – which could actually run our roof AC overnight, or for a full hot day of leaving the cat home alone.

Hopefully by the time we are ready for our next upgrade, lithium prices will have continued their downward trend, and perhaps even more will be known about optimizing real life usage.

Getting Lithium

In the years since we set off down this path – it has gotten a lot easier to get started with lithium.

You have a few options – you can do what we did and buy raw cells and build you own battery. Or there are now a few reputable RV solar installers who are now offering lithium battery installations too, who can do the hard work for you while offering ongoing handholding and support – and a warranty too.

Here are some of the top options worth researching further that we can personally recommend:

AM Solar – Our friends at AM Solar in Eugene, OR have been experimenting with lithium as long as we have and we’ve swapped many notes with them. They at last have put together an offering they feel comfortable enough selling and supporting. They have packages ranging from 100Ah ($1,199) to 400Ah ($3,299) – all including a full battery management system and even all the necessary wiring and fuses.

Starlight Solar – Another solar installer with a great reputation is Starlight Solar in Yuma, AZ. We’ve swapped notes with Larry at Starlight over email for years, and intend to at last go and meet the Starlight crew in person soon while we are in the area. Starlight has also recently begun doing lithium installs, using the same GBS cells and Elite EMS we have in our bus. A friend of ours recently had a 500Ah LFP system installed by Starlight – and from what we have seen they did excellent work.

Build It Yourself:

If you are brave (or foolish) enough to want to tackle building an LFP battery system yourself, there are a lot of cell providers out there catering to the electric car hobbyist market.

The advantage of going this way is that you can likely end up with a much larger system better suited to your personal needs, all for substantially less upfront cost. But this is only a suitable course if you want to get very intimate with your RV’s electrical system, and are comfortable dealing with any potential issues that arise on your own without relying on anyone else for a warranty or support.

Elite Power Solutions – Even though we are disappointed in how our cells from Elite have aged, we are overall happy with the support we have received from the Elite Power Solutions team. They were excited to help us dive into our project 3.5 years ago, and even now they never hold back from honestly and openly answering any of our questions. We know Elite has been working on an installation tips and tricks guide specifically for RVers too – so they are very worth checking in with. They now have a better understanding of using this technology for an RV application, and claim improvements have been made to both the cells and their EMS.

Elite is the US distributor for GBS cells, recognizable by their baby-blue plastic casing.

Balqon – When we built our battery, there weren’t any suitable larger cell options for building an RV house battery bank than the 100Ah cells we found from Elite. Building a battery bank bigger than 100Ah thus meant putting cells in parallel.

Now via Balqon there are cells on the market suitable for building much bigger batteries – the largest single cell we’ve seen being the 1000Ah monster from Balqon. Four of those at $1,200 each would build a massive 1,000Ah 12V battery bank.

Balqon seems to primarily stock the 700AH cell sized right now, with larger and smaller cells currently requiring extended lead time.

Balqon also offers some very interesting energy storage systems that integrate the BMS, relays, and fuses into a complete package. The ESS-12V is a 200Ah system for $1,695, the Lithium Battery Storage 9kwhr is 700Ah for $4,050.

We’ve been very tempted by the potential for Balqon’s bigger cells – especially after having seen 700Ah cells briefly show up as low as $560/ea on Balqon’s clearance page a while ago – a price that actually starts to undercut AGM.

The biggest concern with Balqon is that they have unfortunately built up a reputation for poor customer support amongst those we’ve talked with and read about. Balqon has become known for shipping products late, and without documentation.

I can only share my own experience – after having a great phone call with the CEO of Balqon late last year when we were contemplating a battery upgrade, he sounded excited to sign us up to beta test Balqon’s new BMS. But rather than follow up, he then dropped off the map – never emailing the photos and technical details he promised.

As we were on the fence about being willing to invest in a new bank right away anyway, we weren’t overly motivated to follow-up.

Balqon is the US distribute for Winston cells, recognizable by their bright yellow plastic casing.

The Rainbow of Other Cell Options

We know of other RVers currently using GBS cells from Elite, and Winston cells from Balqon – with overall good results.

But there are several other cell manufacturers that you might run across too, and you can usually tell the manufacturer of a cell by the color. CALB is blue, Sinopoly is black (400Ah for $540 here), Winston is yellow, GBS is pale blue, Hipower is white, and so on. I found a reasonable guide to identifying cells by color here.

But whatever color you go with, whether you build a battery bank yourself or rely on a professional, do your homework and know what you are getting into – not all cells or sellers are created equal!

And do remember – it takes four 3.2V lithium cells to make a 12V battery!

“Drop In” Batteries:

There are some companies wrapping up lithium cells into cases designed to resemble traditional lead batteries, suitable for a “drop in” replacement for existing lead configurations.

We have had almost no contact with anyone who has used these batteries in an RV house battery bank (that’s not to say they’re not out there, they’re just less likely to be out pro-activately sharing about them like DIY pioneers might be) – but for the sake of completeness here are some options for further research:

Lithionics – Lithionics has a huge range of sizes on offer, matching up with traditional vehicle battery sizes. The largest is 600Ah 12V600A-8D that seems to sell for over $9,000 – yikes!

Smart Battery – Smart Battery is another “drop in” provider with a range of sizes on offer, the largest being 500Ah for $5,599.

Premium Batteries:

If you really want to go lithium and you have the upfront budget, the same premium options that I mentioned in 2011 are still out there – primarily targeting the high-end marine market.

If you really want to go lithium and you have the upfront budget, the same premium options that I mentioned in 2011 are still out there – primarily targeting the high-end marine market.

Victron, MasterVolt, and GenaSun ($6,399 for 360Ah) all still offer integrated systems that are the exact opposite of do-it-yourself systems.

But if you want an advanced lithium battery bank with premium support, exploring the options from these manufacturers may be worth it.

Is The Frontier Calling You?

Lithium batteries in RVs might not be as wild of a frontier as it was when we set off exploring in 2011, but it is still an area that is evolving and changing fast.

Things three years from now will likely be even more different than they were three years ago – with more and better options. Hopefully cheaper options too.

So if your current electrical system is doing fine, maybe waiting another year or two is wise.

If you’re at the decision point contemplating a major upgrade, well…

… come on out to the frontier and join us pioneers. A few arrows in the back never killed anyone, right?

*grin*

Has this post been helpful? Has it saved you time, money or from making similar mistakes? We’d love to hear your appreciation – here’s some ideas beyond leaving a comment on how to Say Thanks. (Pssst.. there’s a donate button down below too.. our wine cabinet wouldn’t mind being restocked.)

Posts in this Series:

The Entire Lithium Battery Series

Promise of Lithium #1: Lead Acid Battery Downsides

Promise of Lithium #2: Lithium Ion Battery Advantages

Promise of Lithium #3: Cost Analysis (including our part list)

Boosted Electrons = Better Views (why a boosting inverter rocks!)

Project Notes:

7/2013 — Living in a Parking Lot — Practical use example of our LFP & Boosting Inverter

2/2013 — Lithium Dreams, Lined With Worry? (Response to Boeing Dreamliner Battery Fire)

8/2012 — Our 1 Year Update on our Lithium System

8/2011 — Build Notes: Lithium Ion Battery Success!!

8/2011 — Build Notes: We Built a Lithium Ion Battery Bank

8/2011 — The idea is born: Inverted Intentions (August 2011)

[quote_box_center]Our standard LFP disclaimer — we have no incentive to try to convince anyone else to adopt LFP. We are NOT selling these batteries, we are not affiliates for any of the components, we paid for everything ourselves, we’re not electrical/battery consultants/expert,s nor do we have any financial stake in the technology beyond our own system.

We are simply full time RVing technomads who are designing our own cutting edge home on wheels, and are sharing our independent research & project… because, well, we like to![/quote_box_center]

Hi, all-

We full-time in a 38′ 5th wheel. In April of 2012, we installed 1350W of solar panels on the roof, and a 24V charge controller, 24V/400Ah Concorde AGM battery bank, and 2ea 4KW sine-wave inverter-chargers in the basement. This past December, we discovered that our AGM’s had lost much of their capacity, probably due to temps over 100F in the basement for days at a time in the summers.

Based in part on your experience, we recently replace the AGM’s with a bank of (8) CALB CA400 3.3v/400Ah Lithium cells, with a HousePower BMS for safety. I built a new battery box that takes the place of the steps from the main floor up to the bathroom in the 5th wheel, with the inverters on the nose of the box that projects forward into the basement. The air input side of the inverters and the charge controller are enclosed in an air plenum. Living space air is drawn by a quiet fan into the battery box, passed over the cells, then out into the plenum and through the inverters and charge controller, and finally recirculates back into the living space. Along with near-optimum cell temps, our inverters’ transformer cores & FET’s, as well as the charge controller heat sink, now run around 80-110F rather than 160-200F.

After first spending about a month top-balancing the new bank, we’ve found that our cells tend to settle at about 67% SOC when we have shore power and the float charger is set to 3.30V/cell (13.2V for 12V system, 26.4V for our 24V system), the cells’ open circuit voltage at that SOC, and the cell current is 0. When solar charging is good, the battery’s SOC climbs and can possibly reach as high 100% at the 3.425V/cell that we have our TriStar-60 MPPT solar controller set for. The TriStar is set to immediately drop back to 3.375V per cell to avoid cell overage-charge damage. The float charger is idle during this time, and doesn’t resume output until the cell voltage drops back down to 3.30V. This summer I plan to drop the float charger voltage down just a bit so that the cells settle at a lower SOC and have more SOC headroom for solar accumulation. We’re still experimenting with voltages and collecting data. I have the TriStar connected to our internal WiFi network so we can look at its real-time and data-log web pages on our phones or computers. Geek stuff!

When off-grid, we use our 3000is generator to bring the cells back up some when their SOC is nearing 20% due to insufficient solar gain. The generator can raise the SOC about 20% per hour of gen run time. It’s great that lithium cells neither need nor want to spend any time at full charge.

As you mentioned, very little information is available on the use of lithium batteries in solar service, so I though I would pass along my own experience.

-Jay, retired electronics geek

Many thanks for the wealth of helpful info here, Chris! FYI, an additional series of “drop-in” batteries is available from StarkPower, ranging up to 125 A-h for about $1200 (http://store.starkpower.com/-12V-UltraEnergy-_c_22.html). Does anyone know about the reliability of these batteries? The warranty is only for one year. Thanks! — Brian Keelan

I’ve had StarkPower on my radar for a while now, but I’ve not run across anyone who has shared a first-hand positive or negative experience with their batteries.

I’m curious what cells they are using under the hood – I would be surprised if they are manufacturing their own.

– Chris

Thanks for posting this Chris – and thanks to Dave Ulmer for this link – http://iopscience.iop.org/article/10.1088/1742-6596/395/1/012013/pdf –

I hadn’t seen the article and it’s interesting – not hard to extract some practical tidbits about charge/discharge rate and deep discharging.

Chris – I have a small installation – 200AH of SmartBattery SB100’s, a Progressive Dynamics PD9160AL charger and a Victron BMV-702 monitor in a LTV Unity. I’ve been posting on Sprinter-Forum and the Class B Forum. I just read your addition to this page and re-read the page in the process. I’m in the midst of building a charge controller to switch the charger and alternator, and I’ve spent time thinking about low temperature charging issues (being from Vermont), but not high temp issues. I’d like to get a better handle on present thought on how temp affects battery life when charging and discharging.

In particular, it seems like charging the batteries below freezing is rough on them but discharging is less so. I’ve been assuming that as long as I don’t charge when the batteries are at or below freezing, I won’t hurt their longevity. But I’ve paid no attention so far to the high temp side. Do you have any sense of whether it’s charging, discharging or both that’s affecting your battery life? And is there any online discussion about temp/longevity issues that I should know about, other than here? Thanks – Peter

Hi Peter –

I haven’t found any solidly definitive discussion or data on temperature issues, but if anything is out there I’de love to read it.

But in general, the rule I’ve gone by is to not charge below freezing, and to keep the batteries as cool as possible on the high end. And then to just not worry about it all too much.

Cheers,

– Chris

Hi, appreciate the clarity of your battery pioneer project. I have always loved doing the electrical work, and now with a new to us 5th wheel it is a whole new world to learn. This is definitely bookmarked for future study. Thanks, -brent

Do you charge your LFP battery bank with your vehicle’s alternator? If yes, could you enlighten me a bit on how you’ve wired it all so you don’t cook your alternator/batteries?

I have the alternator bridged to the house batteries via a 500A relay, which I can manually control via a switch on the dash. I only turn it on when we need to charge, or when we are running the roof AC off of alternator power through the inverter.

I don’t leave the charging circuit running non-stop to prevent overcharging the batteries, and I also have the relay triggered to shut off when the lithium EMS triggers a high-voltage alarm – this protects things in case I forget to switch the relay off manually.

Our big bus alternator is rated for continues duty full output, so I don’t have to worry about the alternator burning up under continuous load.

There are some smart alternator regulators (such as this one from Ample Power) that can be programmed to better mate an alternator with LFP batteries, but I have not researched the options too thoroughly.

– Chris

And as a follow on to my prior post, I realized I left out one other factor brought up in the comments; cell memory. So perhaps the List of 4 should be amended to the List of 5 potential aging factors the end user can exert a degree of control over. IF MEMORY IS SHOWN TO BE AN ISSUE with the latest LiFe-PO4 cells.

Which makes me wonder if you have run a capacity test since T1 brought up the subject, given you were mentioning you had been cycling your array more lately (or at least around the time of that post).

thanx

I have never heard of memory effects being observed with LFP cells, but if anyone has any data on that I’d be curious to see it. Usually a “lack of memory” is touted as a lithium advantage.

Cheers!

– Chris

Thank you for all reports helping to unlock the “LPF Code”. I personally think you should set up a paypal donation site to fund the re-purchase of the EXACT SAME ARRAY you have now, and then report on how the pack does over time, with respect to your laundry list of the 4 things to be mindful of (Temperature, Over-floatation, Cells not in balance, and, the notion that today’s LFP cells are better), as being addressed next time around.

As good as this post is -and it’s really good- I found a wealth of wisdom in the comments. As I have it, two questions are raised about cell longevity outside your “List of 4”. One is plain old calendar life, posted by vensonata. The other is this notion of “clogging of the membrane in the battery”, posted by DiDi Wu. The two concepts may be interrelated, or, they may be mutually exclusive.

Either way, both theories have the attribute of being factors outside of our control. So that started me wondering if maybe these factors may have played a significant roll in the loss of capacity you are experiencing. But then poster T1 comes along and states “… we are approaching the 1500 cycles/days in full time use with no apparent loss to date”.

So, that post tends to put the kibosh on the calendar aging and clogging theories. Does it not? Which is outstanding news! For a newbie like me who is putting together his first home based solar system, and could not stomach the idea of Lead-Acid, and desperately seeking an alternative, and looked at nickel-iron, Saline, Lead-crystal… and moved on, T1’s report keeps LPF on the front burner.

So here’s what I’m wondering… you made reference to others getting good life from their LPF arrays… have you found such reports to be valid? In other words are folks reporting good life actually backing up that statement with load testing and whatnot -like you have done- to actually KNOW they are getting good life?

Inquiring minds want to know. :>

Again, thanx for the research.

There aren’t very many other people out there who have large LFP banks that are several years old — so there just isn’t a lot of data to go on, and I have not been keeping track of anyone else’s long term results.

With our own batteries – they seem to have not lost any additional capacity over the past year, and they have been performing very well overall and the cells have been staying well balanced.

I almost wish they were in worse shape – that would make it easier to justify an upgrade to a new and much larger battery bank. But as is, our LFP batteries are 4.5 years old now, and are still performing admirably. *grin*

– Chris

But if anyone wants to donate towards our next LFP system, we do have a ‘Leave a Tip’ button at the bottom of every page

Chris,

I have been a tinkerer of Chinese lithium cells Thundersky, Sinopoly and GBS in somewhat demanding applications since 2007 (2-wheel EV’s) and now I’m a production EV owner (Smart ED) too.

NEVER use float-charging on a Lithium battery pack! If the cells are going to be discharged right away, you charge them to the full amount using CC-CV protocol with a proper BMS system for balancing the cells to the same voltage (about 3.7 volts per cell for GBS) at the end of charge, then stop. If the cells are going to be sitting around a long time without discharge, just charge to no more than 80% (60% is better) and stop.

I suspect your floating the battery pack has been big contributor to premature capacity loss – which may mostly be internal resistance gain.

BTW the 6 year old 4500AH GBS pack in the battery-electric scooter is still doing fine aside from an increase in internal resistance that is affecting the full-throttle performance (120 amps out of the 60AH cells) and charging (prematurely switches to balance mode) in colder weather. The relatively mild summer climate where live (only briefly exceeds 90F a few times per summer) has certainly helped. I may buy a new pack for the scooter than use the old pack for a home backup power system for the house.

Paul D.

Pittsburgh, PA

Hi Paul –

Indeed, for EV usage, floating is not necessary or useful.

But for RV usage where there is a 12V power system that needs to be kept constantly powered it is pretty much unavoidable. The key to preserving battery health in this case seems to be a much lower float voltage – and all the cell manufacturers have dialed back their recommendations on this.

– Chris

Hey Chris – I’m hearing from my pilot friends in the EU that NiMH is becoming the standard. Any thoughts on that technology replacing LiPO?…

Best, and keep up the good work…

Fred Dinkler (aka: da pilot)

Hi Fred —

NiMH is an earlier technology than LFP – and I don’t think it has any substantial advantages.

Aviation is a very conservative industry (for very good reasons!), and new technologies are very slow to get adopted. I am guessing NiMH batteries have been around long enough that they have enough of a proven track record to use in planes. LFP batteries might be where NiMH is now in another 5-10 years.

Cheers!

– Chris

Hi Chris,

Just reviewing your post again as I debate between a 600AH 24V or 300AH 48V system on our vintage Wanderlodge restoration (and all electric conversion) and I’d be keen on your thoughts? I’m thinking I’ll leave the existing 470AH 12V wet cell architecture in place (at least for the time being, while we bed down the LFP higher voltage environment) and leave coach systems on 12v and migrate only the house systems to the LFP bank at 48V (115/230v inverter, AirCon) with DC-DC step downs to 24v (fridge, freezer, lighting, comms, fans) and 12v (chargers & pretty much everything else). We’ve been planning for 9 months+ and are just about to start placing orders for all the expensive bits (yikes!). Just wanted to say that your posts have been extremely helpful both in making the decision to go full time and in getting things planned out to make that happen without truly roughing it. We head to Q by mid January if you are still in the neighbourhood we’d love to make you guys dinner in ‘Das Wunderbus’.

Cheers, Curtis & Ingrid

If you are going with a higher voltage battery system – 48V does have some advantages versus 24V. You will be able to get by with smaller cables, and can use more powerful solar charge controllers. But 24V works well too – the difference will not be huge. You just need to weigh the tradeoffs and see what components are available that fit your needs.

I just heard about a company exhibiting at the RVIA RV industry trade show last week: Volta Power Systems

They seem to have built an RV-focused 48V system that even includes a 10,000W 48V alternator for generating power underway, as well as a 48V LFP battery, and a hefty 48V inverter that seems to be derived from a Magnum design.

It looks primarily intended for the OEM market – but it might be worth looking into for what you are going for.

If our paths cross in Q, I’d love to meet and see the Wunderbus. Keep in touch!

– Chris

FYI – I received an email from Volta Power Systems letting me know that their batteries are not LFP, they are (potentially) something even better.

Volta said:

Sounds very exciting indeed – I am eager to learn more about their tech!

– Chris

Hi Chris,

I’ve bumped to this very technical (but extremely useful) regarding your dying packs. In short, definitely the heat AT full charge that kills it. Jump to minute 5, it’s an eye opener:

https://www.youtube.com/watch?v=pxP0Cu00sZs

In short, when it’s hot, lower the charging full voltage (which is debatable how ‘low’. The presenter gave example of 4.1Volt, but this is not for LFP.

This is very helpful data. We have 840ah of gel cells on our boat and are watching LIPO developments closely. Yours is an issue I have been concerned about from a seat of the pants perspective from watching too many laptop and other small LIPO batteries lose capacity fairly quickly. I hope we get enough data to make a call soon.

Great info and blog. TY

Hey you two! We met at Burning Man at Nomad Camp some years ago. Your adventures and exhaustive record keeping have been among several sources that helped inspire me to go semi-nomadic. I just sold my massive suburban home after a massively over-time-and-budget remodel that ended up paying off anyway. I bought a 2007 Dodge Sprinter van to convert into an off-grid urban stealth camper. I just drove it cross country from Austin to Portland for the first time, averaging about 20 mpg and with only a few minor glitches. Thanks for all your hard work in documenting and publicizing what you do! I’m planning on doing a LiFePO4 battery system with enough solar to keep it topped off in a Texas winter. My friend Chris Robison, does gas-to-electric vehicle conversions for a living and knows a lot about batteries and power electronics. I’ve forwarded him this field report for commend, and I’ll feed them back to you. Sadly the Sprinter got broken into downtown last night, but luckily my deductible is only $250. I’ll probably have them take care of a few other minor problems while it’s in the shop.

Great to hear from you Scott – bummer about being broken into.

Sounds like you are putting together a nice setup – maybe we’ll see you out there. Cheers!

– Chris

I absolutely love the detail and clarity in your posts about lithium power. You’re inspiring the next generation of pioneers!

This summer I’ve been monitoring the temperature of my GBS batteries and find them easy to heat up and slow to cool. I open my bay doors at night to keep them cool. My conclusion is that lithium batteries for RV’s should be configured as long and skinny instead of short and fat to make them cool faster.

I’ve also gone over to all electric cooking with a single induction cooker and electric tea pot. I burn about 500 extra watt-hours a day with this setup. No problem for my 200Ah batteries.

Also got a 2000 watt pure sine-wave inverter and found the refrigerator uses about 30% less power on sine waves. The induction cooktop requires sine waves to work at all.

Enjoy LiFe !!

Hi Dave –

Are your batteries heating up while charging, discharging, or both? Are you sure the batteries are the source of the heat, and not something else in the power bay?

Our batteries don’t seem to heat up much at all – our heat issues in the past were from the batteries being in the same chamber as the inverter/charger without enough ventilation.

Cheers,

– Chris

My batteries only warm a tiny bit due to charging and discharging. Ambient temperature warms them the most and the batteries seem to store the heat real good so after a few 90+ degree days their internal temperature gets into the 100’s and creeps up day by day.

I use a tiny thin thermocouple inserted between the cells to measure the temp.

Has anyone here that has purchased from Balqon received any warranty documentation on their purchase? I’m taking a serious look at their 9Kw battery, but I can’t find warranty info anywhere on their site. Thanks

http://www.balqon.com/store-2/#!/HIQAP-12V-9-kWhr/p/34783145/category=12286435

My name is Les Berg. I’ve been following your blog for years now. Like you, my wife and I are both IT professionals, though we have two kids and a dog. We went ‘nomad’ in 2011, in a 19 foot Komfort travel trailer.

We started looking for a class A RV shortly after, and discovered the GMC 4104 and 4106 buses. We didn’t have the resources for the bus right away, so we bought a 1977 Avco motorhome in 2012.

We liked the idea that the buses are ‘for profit’ vehicles, designed for (relatively) simple and easy maintenance, economical operation, and millions of miles of service. And it’s hard to beat 140-160 gallon fuel tank and 187+ cubic feet of cargo space.

We finally purchased PD4104-1553 a few weeks ago, just 15 miles from ‘home’. It has a solid body, good mechanicals, and possibly a fairly recent rebuild on the motor (though we won’t count on that).

The interior, wiring, and plumbing are all poorly executed and need to be completely replaced. Both AC units are dead, the wall mounted propane heaters are non-vented and dangerous, and it has a household-style water heater. We have our work cut out for us.

I was reading over your posts on lithium battery systems, and I have to say I’m sold. I’ve never been one to do things mainstream, and our overall build plans are eerily similar to yours, including the ‘geek out’. We want the bus to be as independent as possible, so we’re looking to heavily leverage solar power. I’d also looking into the feasibility of building a ‘swamp cooler’ in the old AC bay. We’ll see how that pans out…

Speaking of which, are you still considering selling your lithium system? What would be included, and how much are you asking? This would be a great time to install a this type of system, given that the entire electrical system needs to be redesigned and replaced.

Thanks,

Les

Hi Les —

We are so swamped with other projects this summer I don’t even want to begin contemplating researching and installing a new battery system right now. The current battery is still working fine, so upgrading to more capacity (and selling the old bank) will probably end up being a project for next year.

But it sounds like you are up to creating a great bus home of your own – maybe we will meet out on the road and can geek out someday.

Cheers,

– Chris

A very small print goes with every LiPO batteries… in normal use the battery will degrade about 10% each year due to clogging of the membrane in the battery. it is a physical thing which nobody can solve. .. yet. Even if you don’t use the battery, it will degrade by itself, hence the recommended way to store LiPo is to put it in refrigeration at 80% charge.

I haven’t seen this result documented anywhere – and usually the battery companies are claiming the opposite regarding life over time.

Do you have any sources to share for this? It would be very interesting if true.

– Chris

Chris we are using a Tristar (Morningstar) MPPT-45 controller. Power comes from panels at 90 V and converted to 48 V for the LFP bank. We have had up to 1440 W to controller which is only around 15 amps at 90 V. It would be around 120 amps at 12 V. The inverter is a Magnum 4 kW PSWI. This is used in conjunction with a Mean Well 48 to 12 V converter of 508 W capacity. The Morningstar can be programmed to a number of voltages.

We had problems in Baja and Yucatan with dirty power. The voltage drifted from 60 to 150 V or so and blew microwaves in both places. We purchased a good surge protector after nearly blowing the air conditioner at a state park in Colorado (it “froze”) and the tech who came out to fix it told us to never run without a surge protector. We used this in Yucatan but it was turning off more than it was running. Son Cary and family came down to visit us on beach near Tulum and he brought down a battery charger so that the AC went to battery through battery charger and air conditioner operated through a 1.7 kW power cord. Son designed current system so that the 50 amp inlet is isolated from the battery system and operates only the air conditioner and microwave. He has set the system so that we can operate off shore power through the 1.5 kW battery chargers. If we are ever stuck in a really hot spot, we could go back to the 50 amp circuit. But then we have only used line power once in two years and the generator not at all, but it is nice to have.

Am thinking of putting a remote thermometer in the front bay with the batteries to monitor for excessive heat/cold. Need to put in (pay grandson to put in) a couple of 12 V outlets for 12 V fans and enhanced cross ventilation. A simple mechanic’s light of 50 W should be sufficient to keep the front bay above freezing. We have enough battery to run such for 100 hours. Elaine utilizes a 50 W heating pad for back and knee for several hours. We have changed to all LED (Open Range RVs come with LED in main cabin) except for bottom bay (primary storage area) where the lighting is 4 x 40 W incandescent bulbs. Have left one light on when it has gotten down to 20 F and it has kept that bay above freezing and prevents the water lines from freezing.

Thanks again for sharing your experiences. Reading them helped us decide to go with LFP.

Reed and Elaine Cundiff

Your write-up of capacity loss has been widely quoted, and out of context. Your difficulties have provided the rest of us with information that we take to heart (or at least should take to heart)

We have been using LFP for two years now (have posted before) and are so 1.5 years behind you and Ron Jones. You are the real pioneers.

Our battery suite are CALB cells fabricated by Manzanita Micro.It is a drop in system (after top and bottom balancing). The suite is 4 batteries, each battery is 4 x 180 amp-hr 3.4 V (nominal ) in series. The batteries are in series to make a 180 amp-hr suite at 48 V (nominal) or equivalently a 720 amp-hr 12 V (nominal) suite. We prefer calling it a 8.6 kW-hr system (48 V nominal) or 7 kW-hr usable. We have space for two more batteries but cannot justify the expense/

Techniques and fabrication have developed and our Battery Management Systems charges/absorbs at 3.6 V but floats at 3.4 V (the cells never get above 3.4 V). The BMS is continually balancing cells

We were made aware of high temperature problems and always leave the front bay door open when the inverter is running. The front bay is shadowed by the front overhang of the 5th wheel and the temperature within the bay should not get above ambient. We also leave one of the propane handling doors open for cross-ventilation (the door not in sunlight).

With respect to solar running air conditioning. It will work in the mountain west where temperature/humidity are not as extreme as Florida. We have run a/c for 3.5 hours several times when family was visiting and it was really hot; however, our normal modus is to be out and about during the day, or sitting in the shade provided by the 5th wheel and canopy. We can turn a/c on in early evening for an hour (1.7 kW-hrs if not in sun) and cool cabin down to below 85 which is quite comfortable at low humidity. We then use the 12 V fans for cooling. It would be difficult to run a/c effectively in Florida due to heat and humidity. A 36′ 5th wheel could probably handle up to 2 kW of panels which would run one 15,000 BTU a/c quite nicely..

We have had considerable solar for last few days and have been running power hog Dometic fridge on AC 24 hours a day and the water heater on electric. It is a rainy/cloudy day today and we are using propane. Solar life means varying power management to fit the sun.

Reed and Elaine (currently mootchdocking at older son’s place at 7800′ in mountains of northern New Mexico)

Sounds like you have built a nice well balanced system.

I am curious what inverter/charger you are using? There aren’t a lot of options at 48V – but the higher voltage has a lot of nice benefits.

Cheers!

– Chris

Great write up on Lithium battery power storage. We are at AMSolar now and will have 300Ah bank installed. That is unless I decide on 400Ah. It is a bit pricey… do get the benefit of a 30% fed tax reduction however. That will easy my pain a bit!

Hey guys! Love reading your posts – we’ve recently taken to the road as well. Regarding solar, is it feasible to run an air conditioning unit off solar? We stay mostly in the Florida area and want to boondock. If you’ve ever been in Florida in August, you understand the basis of the question! That being said, we have a 36′ 5th wheel. I assume I could look at the output of the generator in amp-hours and find the equivalent solar/battery bank combination? Thanks in advance for any and all advice.

That being said, we have a 36′ 5th wheel. I assume I could look at the output of the generator in amp-hours and find the equivalent solar/battery bank combination? Thanks in advance for any and all advice.

We get asked this so often, that we recently wrote a post answering this question:

https://www.technomadia.com/2015/02/the-almost-fantasy-of-solar-powered-rv-air-conditioning/

Are your Victron MPPTs a significant source of heat? Trying to decide if we should place them in a separate area from the battery bay to minimize battery heat exposure. The current install has the inverter in a separate area already.

Your experiences have been an invaluable source of both inspiration and information.

The Victron solar controllers are very cool running – they don’t even have/need a cooling fan.

The Inverter however does get hot when bulk charging or inverting heavy loads. That is our biggest heat concern by far.

– Chris

Great post and comments…very informative! I am not a EE, but your comments about heat seem to make perfect sense. I’m wondering if the design of the overall battery pack might play a factor to heat induced loss of performance. Specifically, I’m wondering if the cells in the center of your 4 x 5 power cell are heating up more than the cells on the outer perimeter? I know size is a factor, and you want to keep the wiring to a minimum. But I was wondering if a 2 x 10 design might allow all the cells to stay at a more consistent temp? I’m curious if you can test each cell and see if the center cells are doing better or worse than the cells on the outer ring?

There is no easy way to test the individual cells without substantially disassembling the battery bank, an exceedingly complicated process that isn’t worth the time and effort.

A 2×10 layout would require a lot of tricky wiring – a 4×5 bank makes it easy to bolt the cells together with bus bars. The cells that AM Solar is offering however do seem to lend themselves better to alternative configurations.

Cheers,

– Chris

Do these LFP batteries really have to be strapped together? Or is this just being done for the convenience of rigid straps between terminals? Could flexible battery cables be used as well? How critical is the cell balancing and a factory BMS to manage it? What would happen if I bought 4 Balqon 3.2V cells of a certain AH rating, wired them up in series and charged the lot with a 3-stage converter when on shoreline power and with a solar controller controlled in detail (times, voltages, and current) by a Trimetric meter? I always wondered why my L-Ion computer battery (with 6 cells inside) seemed to have 8 or so connectors instead of just 2. Is this where the answer lies?

These are probably questions best addressed to the battery supplier you’re considering.. they’ll be able to advise you on the best setup for your needs. We only have experience with the cells we purchased and installed, and Elite Power was awesome at answering our questions. Thanks.

We sold our stick house in ’94, have been living full time in a bus we converted for over 20 years. Totally off the grid. We don’t use “hook ups” or run a generator very much. Started off with 1300 watt inverter about 500 watts solar and 4 L-16 batteries that lasted 11 years. Now have 4000 watt inverter and 600 watt true sine wave inverter, 1570 watts of solar and 10 AGM 8D batteries that are nearing the end of their expected life span but still working good. The battery bank is set up 24 volts using them for starting the bus and the house. We now have an electric fridge and freezer (started with propane RV fridge) along with all the rest of the things like 2 puters and TV running a lot and microwave, toaster, waffle cooker and all the gadgets in a normal house and small shop. I really appreciate you sharing your experiences lithium batteries, I love the AGMs but 1,650 pounds of battery is a lot to pack around. I am planning our next battery bank thinking LITHIUM. Thanks for all your documentation!

Sounds like you have built a great system – and LFP batteries will make it even more epic. Thanks for sharing!

– Chris

I have been using one pack of GBS LFP cells for just over a year now and think I have detected about a 10% loss of capacity. I cycle the battery to about 60% DoD per day all year around. I just bought a second GBS pack from http://www.batteryspace.com and find the new pack is 1/2 inch wider and 1/4 inch longer than the older pack. They don’t fit together very well but I am using the new and old packs in parallel and they are performing very well. I’m a fulltime RVer.

Interesting that the newer and older GBS cells no longer mesh together. I had heard that the newer GBS cells actually had a bit more actual capacity (compared to rated capacity) – the slightly larger physical size probably explains it.

– Chris

Now that all Tesla’s patents are open, can’t a floor-integrated battery pack like that be made thru a DIY project?

I don’t know of any Tesla patents that are relevant to RV battery banks, but more innovation and people experimenting is always a good thing.

Great write-up, thanks!

Not sure whether this has been mentioned or not (lots of comments!!), but my guess temperature has probably killed most of your capacity (not necessarily float).

From white paper here: http://www.battcon.com/PapersFinal2008/McDowallPaper2008PROOF_9.pdf

“Metal dissolution from the positive is exacerbated by temperature. Manganese (spinel) is particularly soluble, resulting in rapid capacity fading. Iron phosphate also shows solubility above 40 °C to 45 °C, making it less suitable for high-temperature applications such as telecom outside plant. NCA and to a lesser extent NMC exhibit the lowest solubility of their metals, which translates into longevity, especially at elevated temperature.”

My guess is most of your battery has experience temperature above 45C easy.

Also, regarding Tesla, since they use NCA batteries, they wouldn’t suffer that much. Where as Nissan Leaf (which use Manganese), does suffer from temperature. It seems the theory from that whitepaper is consistent from the practice, so far.

Great comment Rudy, thanks for the link to the white paper.

Temperature is indeed my top choice villain right now. I am monitoring battery temperatures closely now, and will be curious to see if keeping them cooler will reduce the rate of aging.

Cheers,

– Chris

Hello Chris, Thanks for being the science guinea pig. I have been researching lifepo4 and other lithium batteries for some time. (BY the way I run an off grid monastery with 11.4 kw Pv array and have been through two 80kwh battery banks, the first wet lead, the second AGM. And am now on the third AGM installed November 2014. only 40 kwh this time…all banks were 48 volts. Wet lead lasted 7 years, AGM 6 years. (2250 cycles) and quite a number of incomplete winter charges which in fact did not seem to damage them much. The present Surrette AGM are good quality and usually do not cycle below 20% so I expect 8 years. So about $1000 year, to run a 10,000 sq ft building with up to 20 people in residence in the mountains of B.C. Canada.

So that brings us back to Lifepo4. I have been conversing on Electrodacus site about a hidden factor (which is not hidden lithium battery makers at all) and that is “calendar life” OH OH. Cycle life is real…but only within a limited time frame! Your giant bottle of vitamins that you figured would last you 5 years has a best before date so unless you eat 5 per day you will have to throw most of the bottle out! Saft batttery of France (NASA use their lithium batteries) says calendar life is 5-15 years. Yikes, man! 3000 cycles to 80% DOD is 8 years…better use them. The new Winston lithium ytrium iron phosphate has 5000 cycles to 80%, and 7000 cycles to 70%. Now unless they solved the ageing time element (related to heat but not the same as heat…a kind of gunk build up between the lithium and the graphite anode). So buyer beware. Ahem…Tesla roadster battery expectation 70% remaining after 5 years or 50,000 miles. That is out of Elon Musks mouth. 50,000 miles is only 200 cycles at 250 miles per cycle!!! Ok, so now you know: forget cycle life it doesn’t factor in anywhere near as important as heat degradation and the mysterious “calendar life”. To understand more see Professor Jeff Dahn’s lecture on youtube “Why do li-ion batteries die and how to improve the situation.” He is the Prof who trained the PHd’s that Tesla hired…so the dude knows and abides!

Great comment, Ven. And indeed – calendar life may emerge as a major potential issue.

The science of how LFP batteries age is only just now being figured out – that is what makes this bleeding edge turf only suitable for people who are willing and able to be pioneers.

I imagine ten years from now this will all be rote boring stuff.

BTW – solar monastery… Cool! *grin*

– Chris

Great info! I recently found some YouTube videos by an electrical engineer who goes by electrodacus. He created a cool BMS (battery management system) specifically designed for his off grid setup with lithium ion storage. Perhaps a better BMS would assist as well. Temp issues are concerning.

Anyone have any other experience with Balqon? Chris, I wonder if the sudden lack of followup to your phone call with them might have had something with their legal or marketing folks getting cold feet about a high visibility blog series? Sometimes it’s not about the reality of the product, sometimes it’s about legal/marketing saying “what if”? They certainly have some pretty compelling offerings if their support/warranty/quality is decent. http://www.balqon.com/store-2/#!/Lithium-Battery-Storage-15-kwhr-1-week-Lead-Time/p/39083041/category=12269141 in particular looks like an excellent potential replacement for our 3 seriously moribund 8D AGM batteries.

Chris, if you were going to buy a new inverter today to work with Solar and Lithium batteries, what would be on your short list? :p

Thanks again to Chris and all the commenters, this is hugely helpful, hope to catch up with some of you on the road!

The online forums I have skimmed are full of stories of Balqon not following up – so I don’t think it is just us.

But their product line does look very compelling – and if I was starting from scratch I’d definitely keep hounding them. But since we have batteries that are working good (just not great) it isn’t worth putting too much effort into pursuing a Balqon upgrade for the time being.

As for inverters… Victron would still be at the top of my list, but the Magnum Hybrid is definitely worth considering too.

Cheers,

– Chris

Chris,

After much digging and looking I think the Victron is our likely solution. I don’t see anything compelling on the Magnum Hybrid, at least in the readily available info. The Victron Multiplus simply has better efficiency and (much) lower phantom load. Do you know if there have been changes to Victron’s current units ability to effectively charge LiFePO4 batteries? Given your recent revelations about charging LiFePO4 and the impact on longevity, how would you configure a Victron from the start?

Really appreciate your having been through so much of this already, it’s invaluable to those of us just starting down the same road now. I think we’re probably going to go with the Balqon 15 kw. Assuming that we need to stay with 12 volt vs. 24 volt. The 24 volt get better efficiency from what I can see. going to 24 volt would interact with the existing 12 volt loads and with the planned for Solar array installation.

Finally, I think we owe you some beer, hard cider or whatever your libation of choice may be. We may well hit you guys up for a consult on mobile and electrical as we’re a family hitting the road to build community based websites (our profession) on the road. Your site has been a tremendous help to us in making this transition and planning our remodel to make our older Foretravel our new home.

Hi James –

I didn’t realize the Victron had lower phantom draw than the Magnum – that is a significant consideration.

Everything is more efficient at 24V than 12V – if you can build a majority-24V system that would be a great way to go. The 24V solar controllers and inverters all have advantages over 12V, and it makes it easier to build a big battery too. The only downside is integrating with existing 12V systems.

As for configuring the Victron – it is fully programmable, so I’d just go with whatever the latest recommendations from your battery supplier are, and then tweak from there.

Looking forward to sharing a libation or three with you somewhere down the road,

– Chris

Just a “heads up” for your readers reference Smart Battery in Tampa, Florida. The company has a “F” rating from the Tampa BBB with a growing list of complaints. Smart Battery LLC is under investigation by the Hillsborough County Comsumer Protection office for consumer fraud.

While I think “drop-in” lithiums are a good choice for many of us, this company seems to have serious issues.

Yikes. REALLY appreciate the heads up on possible issues with Smart Battery. Obviously some due diligence is in order regarding the company if that’s what you’re seeing.

::sigh:

Where to go for Lithium installation? Are there any other decent drop-in replacement options? IIRC AM Solar had a bad experience working with Lithonics, and if Smart Battery is DOA as an option as well, we’re going to need to find somewhere that can help with the install. Wish we were a lot cooler to either Yuma AZ or Springfield OR!

Please, try this place for replacement LIP battery. http://www.balqon.com

SKU:# WBQ-LYP1000AHC, 1000 AHr battery for $1200.00.

Hi Steven —

What you are referencing isn’t a battery – it is a single cell. It takes four LFP cells to make a 12V battery.

Those Balqon 1000Ah cells are the largest single cells I know of (Balqon did have a 1250Ah cell for a while, but it is no longer listed), and they offer a LOT of amp-hours for the money.

The deal used to be even better – Balqon just raised prices on all their cells by 20% in October. Before that, these cells were $1000/ea.

And when I first saw this cell listed on the Balqon site in early 2013, it was initially priced at $900/ea – with some available on clearance for $740/ea.

At those prices, LFP is actually starting to substantially undercut AGM!

Hopefully Balqon prices will drop again – they are definitely a company on our radar.

Cheers,

– Chris

Really appreciate all your efforts and following both the Lithium battery and solar series with intense interest.

We’re looking at putting in a large Lithium house bank as well and while researching I ran across some interesting information about the Smart Battery direct replacement units. The amp hr stat they list is for 100% available discharge! I think they are actually packaging up a 375 amp hr battery and selling it as a 300 with a protection system that doesn’t allow you to drain it to the point where there is damage.

Building a battery that internally won’t allow itself to be damaged by excessive discharge or overcharging seems like a really REALLY good idea. Especially in an environment like an RV where occasionally things happen that lead to discharging a lot more than intended, people being people.

I had NOT considered the heat issue, though in retrospect it makes total sense. Our existing bank is in a housing in the heated basement next to the diesel fuel tank. The housing is sized and built to hold 4 8D batteries, but we’re looking at replacing them with 2 300 amp hr Smart Batteries so we should have some decent ventilation around them. I suppose I should try and get a remote temperature monitor down there so I can get a bead on how hot it gets. Might be able to rig some thermostat controlled ventilation? What do you think would be a good temp to start pulling in cooler air? Or do you hold with the “put them inside so they can stay cool like the cats?” school of thought given your experiences?

Thanks in advance for your thoughts and suggestions!

James

The advantage of having your batteries inside is that it becomes a lot easier to keep aware of the temperatures (cold or hot) they are being exposed to. You should be just fine with batteries in a utility bay too, as long as you don’t ignore them and keep an eye on the temperature. A remote probe can certainly help.

The LFP batteries don’t generate a lot of heat while being charged, so as long as there aren’t other heat sources around you may not need active ventilation to bring in cool air. But you’ll have to experiment to know for sure what works for you.

I will be very interested to hear how things go with Smart Battery – I haven’t run across anyone who has shared a first hand report on how their batteries have worked out. Do let us know if you go with them.

– Chris

Oh…and forgot one more comment…

AGM batteries ARE lead-acid batteries. Built with fiberglass fabric between the plates true, but they still use lead plates and sulfuric acid diluted with water. They are not some mythical different kind of beastie.

You got your open cell flooded lead-acid – FLA.

You got your sealed valve-regulated lead-acid – VRLA.

You got your sealed flooded lead-acid – VRLA FLA.

You got your sealed lead-acid with fiberglass matting between the lead plates – VRLA AGM.

You got your sealed lead-acid with goop added to the electrolyte to make it into a jelly – VRLA GEL.

And then of course, you’ve got various different metals mixed with lead to make alloy plates, and you’ve got your pure lead plates.

But they are all just variations of the chemistry experiment known as “a lead-acid battery”.

Indeed – the basics of lead battery chemistry has been essentially unchanged for a hundred years, and AGM is just the latest variation on a very old theme.

This was all discussed in more depth in the older posts in this series too.

Cheers!

– Chris

A few comments.

The image, “AGM vs. FLP Cost/Cycle” contains an error, which invalidates the final cost totals comparison. Specifically, at 50% depth of discharge, the average AGM will have around 1000 cycles of life, not the 500 shown in the image. Double the life cycles and cut the cost per cycle in half and you end up with six of one, half dozen of the other in terms of cost per cycle.

Another point…

Lead-acid batteries DO NOT BOIL!

When charging, the process that takes place is electrolysis, in which electrons flowing through the electrolyte come into contact with molecules of H2O and cause the individual components to release from each other, separating into H, H, and O. The freed hydrogen and oxygen forms bubbles which rise to the surface. This occurs any time a lead-acid battery is being charged – at any temperature.

The one commenter’s idea that EQing was causing the crud to “boil from the plates” is just dead wrong. That is not at all what is happening.

Equalizing (or any other form of overcharging) can and will elevate the temperature of a lead-acid battery. But if it ever raised the battery to a temperature which would boil water, that battery would be ruined.

Lead-acid battery max allowable temps are usually less than 150 degrees F. Even at 18,000 ft. elevation, the boiling point of water is above 180 degrees F.

Keep up the good work Chris! Cheers.

For the simple cost/cycle chart, we used the most conservative published value I could find for representative cells – I believe this was explained in the original post on the topic.

Indeed many AGM batteries are actually rated for 1000 cycles at 50%, but I could have then used a 4000 cycle LFP rating which is also seemingly common. I’ve even seen lab tests showing some LFP cells still giving nearly 100% capacity after thousands more cycles than that.

The big challenge with LFP however is just how little real world long-term testing there is to compare how actual usage and capacity impacts match up to the lab tests.

As for the boiling… Indeed – while lead batteries being charged are not actually at a technical boiling point, the acid is bubbling and churning away so that it sounds like a rolling boil when under an equalization charge.

So while not technically accurate – the term “boiling” has become common to describe that process.

Thanks for sharing the more detailed explanation of what is going on behind the scenes though – I am sure it will help some people have a better understanding.

– Chris